∑ 125∞C operation

∑ 1 µs transient response

∑ >3.5 million hours MTBF

∑ Typical efficiency 94% at 2 V/50 A

∑ No output filtering required

∑ BGA or J-Lead packages

Vicor Corporation

Tel: 800-735-6200 V∑I Chip Voltage Transformation Module V048K020T080 Rev. 1.2 Page 1 of 15

vicorpower.com

PRELIMIN

ARY

Product Description

The V048K020T080 V

∑

I Chip Voltage Transformation

Module (VTM) breaks records for speed, density and

efficiency to meet the demands of advanced DSP,

FPGA, ASIC, processor cores and microprocessor

applications at the point of load (POL) while providing

isolation from input to output. It achieves a response

time of less than 1 µs and delivers up to 80 A in a

volume of less than 0.25 in

3

while providing low output

voltages with unprecedented efficiency. It may be

paralleled to deliver hundreds of amps at an output

voltage settable from 1.1 to 2.3 Vdc.

The VTM V048K020T080's nominal output voltage is

2 Vdc from a 48 Vdc input factorized bus, V

f

, and is

controllable from 1.1 to 2.3 Vdc at no load, and from

1.1 to 2.2 Vdc at full load, over a V

f

input range of 26

to 55 Vdc. It can be operated either open- or closed-loop

depending on the output regulation needs of the

application. Operating open-loop, the output voltage

tracks its V

f

input voltage with a transformation ratio,

K = 1/24, and an output resistance, R

OUT

= 1.3 milliohm, to

enable applications requiring a programmable low

output voltage at high current and high efficiency.

Closing the loop back to an input Pre-Regulation

Module (PRM) or DC-DC converter can compensate

for R

OUT

.

The 2 V VTM achieves break-through current density of

320 A/in

3

in a V

∑

I Chip package compatible with

standard pick-and-place and surface mount assembly

processes. The V

∑

I Chip BGA package supports in-board

mounting with a low profile of 0.16" (4 mm) over the

board. A J-lead package option supports on-board

surface mounting with a profile of only 0.25" (6 mm)

over the board. The VTM's fast dynamic response and

low noise eliminate the need for bulk capacitance at the

load, substantially increasing the POL density while

improving reliability and decreasing cost.

Absolute Maximum Ratings

Parameter

Values

Unit

Notes

+In to -In

-1.0 to 60.0

Vdc

+In to -In

100

Vdc

For 100 ms

PC to -In

-0.3 to 7.0

Vdc

TM to -In

-0.3 to 7.0

Vdc

VC to -In

-0.3 to 19.0

Vdc

+Out to -Out

-0.1 to 4.0

Vdc

Isolation voltage

2,250

Vdc

Input to Output

Operating junction temperature

-40 to 125

∞C

See Note

Output current

80

A

Continuous

Peak output current

120

A

For 1 ms

Case temperature during reflow

208

∞C

Storage temperature

-40 to 150

∞C

Output power

174

W

Continuous

Peak output power

261

W

For 1 ms

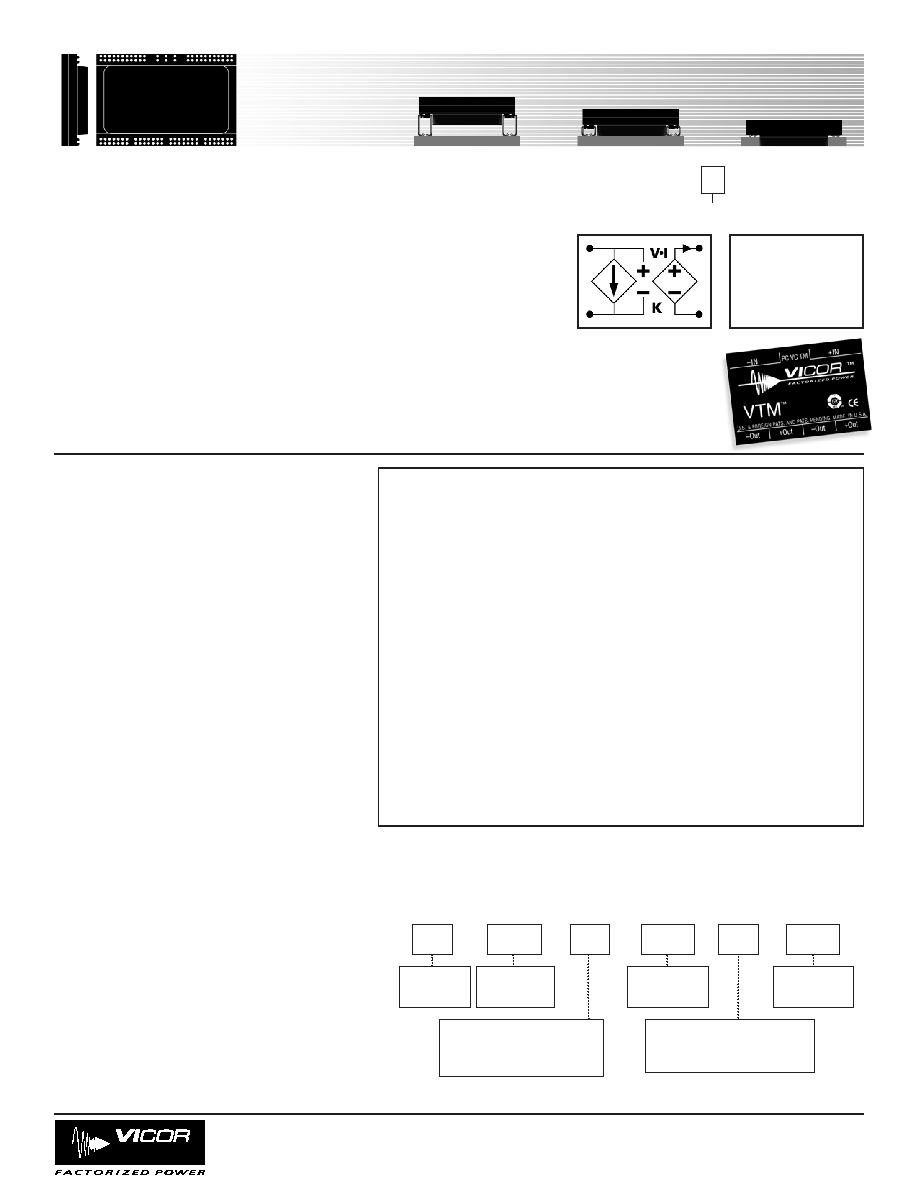

V∑I Chip

TM

≠ VTM

Voltage Transformation Module

∑ 48 V to 2 V V∑I Chip Converter

∑ 80 A (120 A for 1 ms)

∑ High density ≠ 320 A/in

3

∑ Small footprint ≠ 75 A/in

2

∑ Low weight ≠ 0.5 oz (14 g)

∑ Pick & Place / SMD

V048K020T080

V

f

= 26 - 55 V

V

OUT

= 1.1 - 2.3 V

I

OUT

= 80 A

K = 1/24

R

OUT

= 1.5 m

max

Actual size

©

VTM

Note:

The referenced junction is defined as the semiconductor having the highest temperature.

This temperature is monitored by the temperature monitor (TM) signal and by a shutdown comparator.

K indicates BGA configuration. For other

mounting options see Part Numbering below.

Output Current

Designator

(=I

OUT

)

V

048

K

020

T

080

Voltage

Transformation

Module

Input Voltage

Designator

Product Grade Temperatures (∞C)

Grade

Storage

Operating

T

-40 to150

-40 to125

Configuration Options

F = On-board (Fig.15)

K = In-board (Fig.14)

Output Voltage

Designator

(=V

OUT

x10)

Part Numbering

Vicor Corporation

Tel: 800-735-6200 V∑I Chip Voltage Transformation Module V048K020T080 Rev. 1.2 Page 2 of 15

vicorpower.com

PRELIMIN

ARY

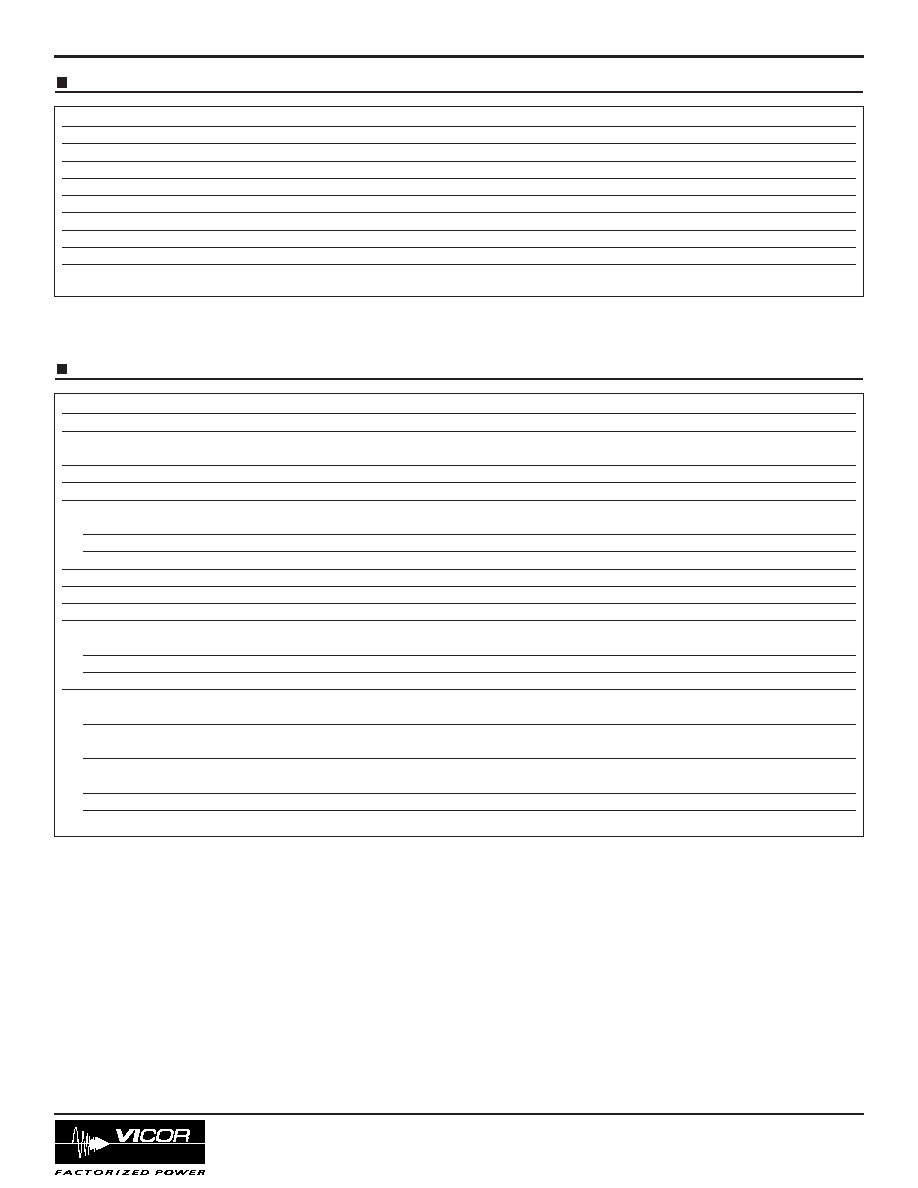

Specifications

Parameter

Min

Typ

Max

Unit

Note

Input voltage range

26

48

55

Vdc

Operable down to zero V with external bias voltage

Input dV/dt

1

V/µs

Input overvoltage turn-on

56.0

Vdc

Input overvoltage turn-off

59.5

Vdc

Input current

3.7

Adc

Input reflected ripple current

170

mA p-p

Using test circuit in Fig.16; See Fig.1

No load power dissipation

2.50

3.15

W

Internal input capacitance

4

µF

Internal input inductance

20

nH

INPUT (Conditions are at 48 Vin, full load, and 25∞C ambient unless otherwise specified)

Parameter

Min

Typ

Max

Unit

Note

Rated DC current

0

80

Adc

Peak repetitive current

120

A

Max pulse width 1ms, max duty cycle 10%,

baseline power 50%

DC current limit

82

99

112

Adc

Current share accuracy

5

10

%

See Parallel Operation on page 10

Efficiency

Half load

94.0

94.2

%

See Fig.3, 2 Vout

Full load

93.0

93.2

%

See Fig.3, 2 Vout

Internal output inductance

0.8

nH

Internal output capacitance

306

µF

Effective value

Load capacitance

56,300

µF

Output overvoltage setpoint

2.33

Vdc

Output ripple voltage

No external bypass

53

65

mV

See Figs.2 and 5

100 µF bypass capacitor

2

mV

See Fig.6

Effective switching frequency

2.52

2.65

2.78

MHz

Fixed, 1.33 MHz per phase

Line regulation

K

0.0413

1/24

0.0421

V

OUT

= K∑V

IN

at no load

Load regulation

R

OUT

1.3

1.5

m

See Fig.19

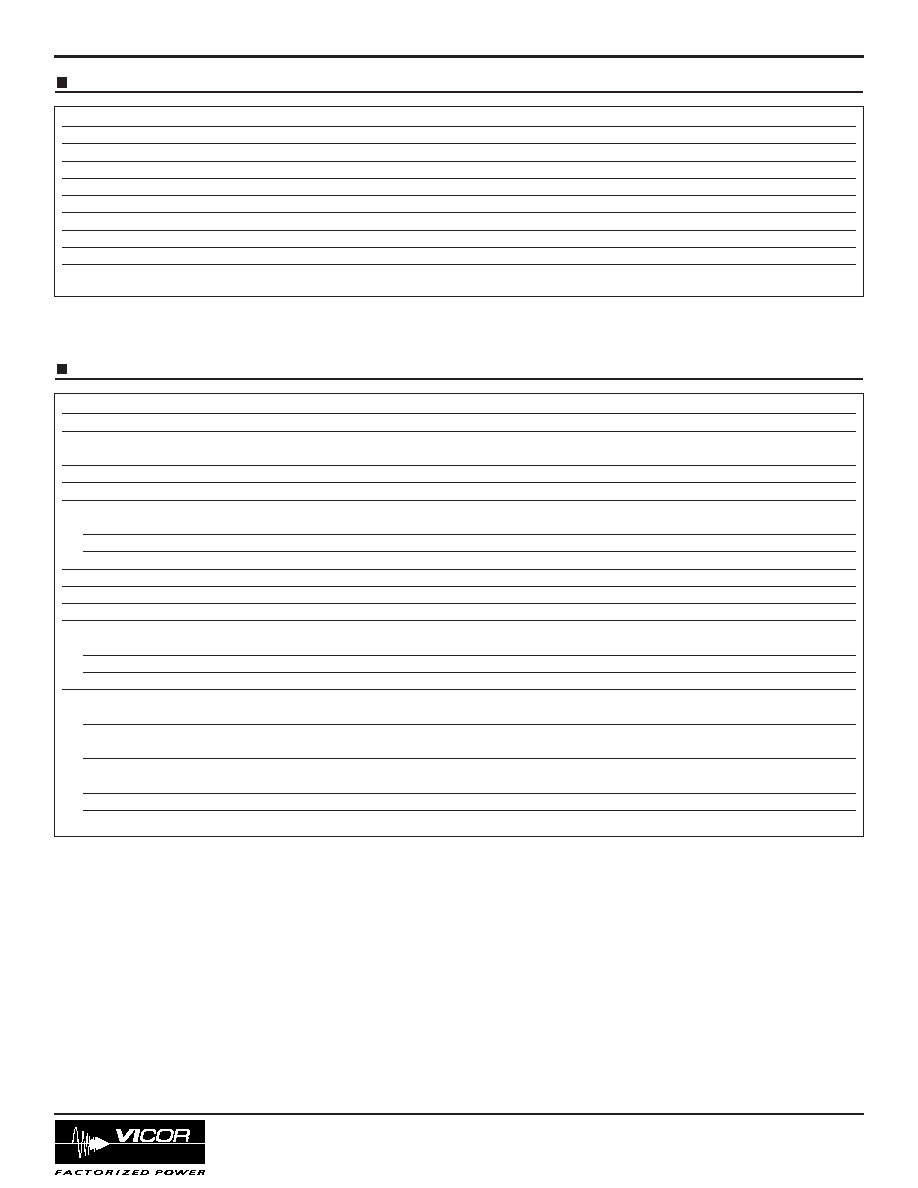

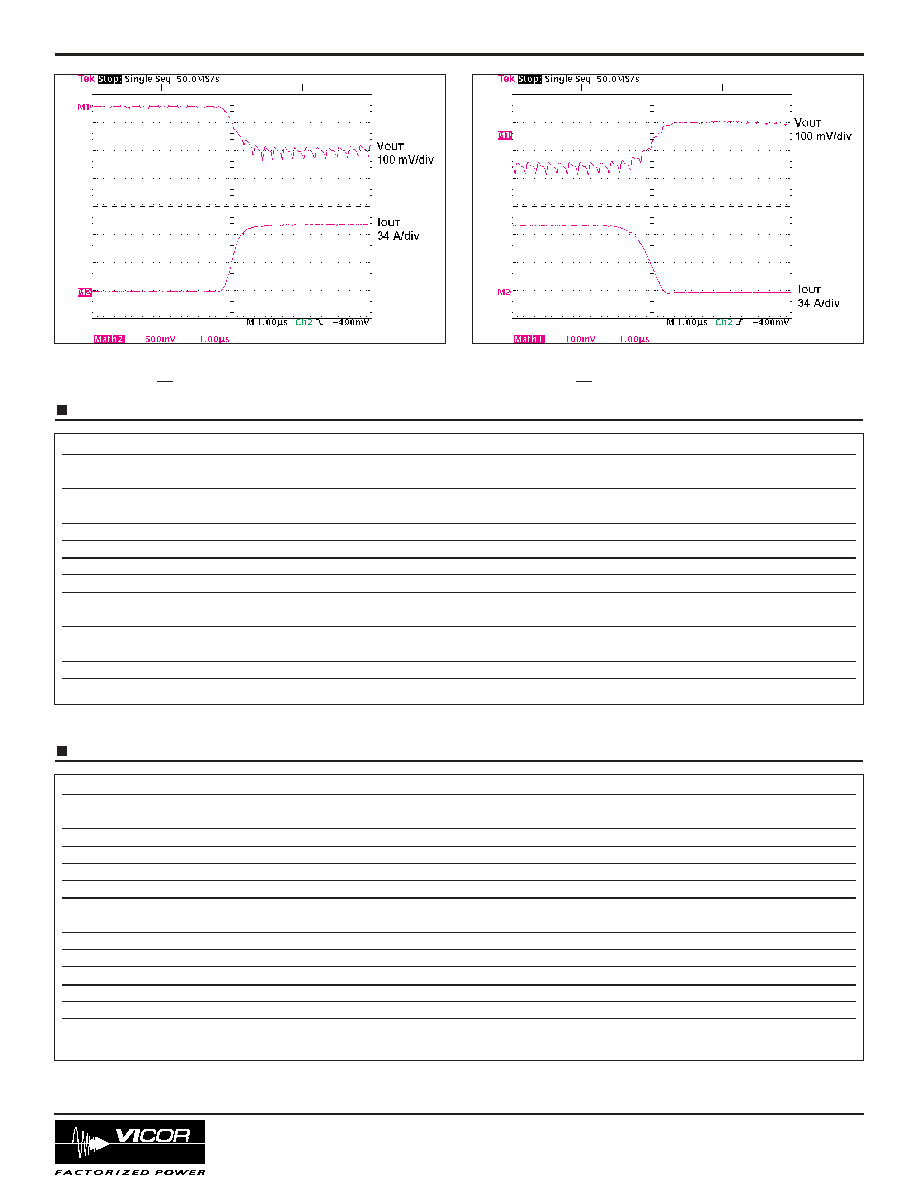

Transient response

Voltage overshoot

20

mV

80 A load step with 100 µF C

IN;

See Figs.7 and 8

Response time

200

ns

See Figs.7 and 8

Recovery time

1

µs

See Figs.7 and 8

OUTPUT (Conditions are at 48 Vin, full load, and 25∞C ambient unless otherwise specified)

Vicor Corporation

Tel: 800-735-6200 V∑I Chip Voltage Transformation Module V048K020T080 Rev. 1.2 Page 3 of 15

vicorpower.com

Specifications

Figure 1-- Input reflected ripple current at full load and 48 Vin

Efficiency vs. Output Current

85

86

87

88

89

90

91

92

93

94

95

0

10

20

30

40

50

60

70

80

Output Current (A)

1.2 V

1.5 V

1.8 V

2.0 V

Efficiency (%)

Figure 3-- Efficiency vs. output current and output voltage

Power Dissipation vs. Output Current

0

2

4

6

8

10

12

14

0

10

20

30

40

50

60

70

80

Output Current (A)

1.2V

1.5V

1.8V

2.0V

Power Disipation (W)

Figure 4--Power dissipation as a function of output current and

output voltage

WAVEFORMS

Figure 6--Output voltage ripple at full load and 2 Vout with

100 µF ceramic external bypass capacitance and 20 nH

distribution inductance.

Figure 5-- Output voltage ripple at full load and 2 Vout;

without any external bypass capacitor.

Output Ripple vs Load

0

10

20

30

40

50

60

0

10

20

30

40

50

60

70

80

Output Currrent (A)

Output Ripple (mV)

Figure 2-- Output voltage ripple vs. output current at 2 Vout

with no POL bypass capacitance.

Vicor Corporation

Tel: 800-735-6200 V∑I Chip Voltage Transformation Module V048K020T080 Rev. 1.2 Page 4 of 15

vicorpower.com

PRELIMINARY

Parameter

Min

Typ

Max

Unit

Note

Primary Control (PC)

DC voltage

4.8

5.0

5.2

Vdc

Module disable voltage

2.4

2.5

Vdc

Module enable voltage

2.5

2.6

Vdc

Current limit

2.4

2.5

2.9

mA

Source only

Disable delay time

4

10

µs

PC low to Vout low

Temperature Monitor (TM)

27∞C setting

3.00

Vdc

Operating junction temperature

Temperature coefficient

10

mV/∞C

Full range accuracy

±5

∞C

Operating junction temperature

Current limit

100

µA

Source only

VTM Control (VC)

External boost voltage

12.0

14.0

19.0

Vdc

Required for VTM start up without PRM

External boost duration

10

ms

Vin must be >26 V for VTM to remain operating

without boost voltage.

Specifications, continued

Auxiliary Pins (Conditions are at 48 Vin, full load, and 25∞C ambient unless otherwise specified)

Parameter

Min

Typ

Max

Unit

Note

MTBF

MIL-HDBK-217F

3.5

Mhrs

25∞C, GB

Isolation specifications

Voltage

2,250

Vdc

Input to Output

Capacitance

2,500

pF

Input to Output

Resistance

10

M

Input to Output

Agency approvals (pending)

cTÐVus

UL/CSA 60950, EN 60950

CE Mark

Low voltage directive

Mechanical parameters

See mechanical drawing, Figs.10 and 12

Weight

0.5 / 14.0

oz / g

Dimensions(BGA version)

Length

1.26 / 32

in / mm

Width

0.85 / 21.5

in / mm

Height

0.23 / 5.9

in / mm

GENERAL

Figure 7-- 0-80 A step load change with 100 µF input

capacitance and no output capacitance.

Figure 8-- 80-0 A step load change with 100 µF input

capacitance and no output capacitance.

Vicor Corporation

Tel: 800-735-6200 V∑I Chip Voltage Transformation Module V048K020T080 Rev. 1.2 Page 5 of 15

vicorpower.com

PRELIMIN

ARY

Specifications, continued

V∑I CHIP STRESS DRIVEN PRODUCT QUALIFICATION PROCESS

Symbol

Parameter

Min

Typ

Max

Unit

Note

Over temperature shutdown

125

130

135

∞C

Junction temperature

Thermal capacity

0.61

Ws/∞C

R

JC

Junction-to-case thermal impedance

1.1

∞C/W

R

JB

Junction-to-BGA thermal impedance

2.1

∞C/W

R

JA

Junction-to-ambient

1

6.5

∞C/W

R

JA

Junction-to-ambient

2

5.0

∞C/W

THERMAL

Notes

1. V048K020T080 surface mounted in-board to a 2" x 2" FR4 board, 4 layers 2 oz Cu, 300 LFM.

2. V048K020T080 with a 0.25"H heatsink surface mounted on FR4 board, 300 LFM.

Test

Standard

Environment

High Temperature Operational Life (HTOL)

JESD22-A-108-B

125∞C, Vmax, 1,008 hrs

Temperature cycling

JESD22-A-104B

-55∞C to 125∞C, 1,000 cycles

High temperature storage

JESD22-A-103A

150∞C, 1,000 hrs

Moisture resistance

JESD22-A113-B

Moisture sensitivity Level 5

Temperature Humidity Bias Testing (THB)

EIA/JESD22-A-101-B

85∞C, 85% RH, Vmax, 1,008 hrs

Pressure cooker testing (Autoclave)

JESD22-A-102-C

121∞C, 100% RH, 15 PSIG, 96 hrs

Highly Accelerated Stress Testing (HAST)

JESD22-A-110B

130∞C, 85% RH, Vmax, 96 hrs

Solvent resistance/marking permanency

JESD22-B-107-A

Solvents A, B & C as defined

Mechanical vibration

JESD22-B-103-A

20g peak, 20-2,000 Hz, test in X, Y & Z directions

Mechanical shock

JESD22-B-104-A

1,500g peak 0.5 ms pulse duration, 5 pulses in 6 directions

Electro static discharge testing ≠ human body model

EIA/JESD22-A114-A

Meets or exceeds 2,000 Volts

Electro static discharge testing ≠ machine model

EIA/JESD22-A115-A

Meets or exceeds 200 Volts

Highly Accelerated Life Testing (HALT)

Per Vicor Internal

Operation limits verified, destruct margin determined

Test Specification*

Dynamic cycling

Per Vicor internal

Constant line, 0-100% load, -20∞C to 125∞C

test specification*

* For details of the test protocols see Vicor's website.

Test

Standard

Environment

BGA solder fatigue evaluation

IPC-9701

Cycle condition: TC3 (-40 to +125∞C)

IPC-SM-785

Test duration: NTC-B (500 failure free cycles)

Solder ball shear test

IPC-9701

Failure through bulk solder or copper pad lift-off

V∑I CHIP BALL GRID ARRAY INTERCONNECT QUALIFICATION

Vicor Corporation

Tel: 800-735-6200 V∑I Chip Voltage Transformation Module V048K020T080 Rev. 1.2 Page 6 of 15

vicorpower.com

PRELIMINARY

PRELIMIN

ARY

Pin/Control Functions

+IN/-IN DC VOLTAGE PORTS

The VTM input should not exceed the high end of the range

specified. Be aware of this limit in applications where the VTM

is being driven above its nominal output voltage. A 14 V source

must be applied to the VC pin and voltage must be present at

the +In and -In ports in order for the VTM to process power. If

the input voltage exceeds the over voltage lock-out, the VTM

will shutdown. The VTM does not have internal input reverse

polarity protection. Adding a properly sized diode in series with

the positive input or a fused reverse-shunt diode will provide

reverse polarity protection.

VC ≠ VTM Control

The VC port is multiplexed. It receives the initial Vcc voltage

from an upstream PRM, synchronizing the output rise of the

VTM with the output rise of the PRM. Additionally, the VC

port provides feedback to the PRM to compensate for the VTM

output resistance. In typical applications using VTMs powered

from PRMs, the PRM's VC port should be connected to the

VTM VC port.

In applications where a VTM is being used without a PRM,

14 V must be supplied to the VC port for approximately 10 ms in

order for the VTM to startup. The VTM can be operated at

input voltages below 26 V as long as the VC voltage is applied.

PC ≠ Primary Control

The Primary Control (PC) pin is a multifunction pin for

controlling the VTM as follows:

Disable ≠ If the PC is left floating, the VTM output

is enabled. To disable the output, the PC pin must be pulled

lower than 2.4 V, referenced to -In. Optocouplers, open

collector transistors or relays can be used to control the PC

pin. Once disabled, 14 V must be re-applied to the VC pin

in order to restart the VTM

Primary Auxiliary Supply ≠ The PC port can source up to

2.4 mA at 5 Vdc.

TM ≠ Temperature Monitor

The Temperature Monitor (TM) provides a linear output

proportional to the internal temperature of the VTM. At 300∫K

(+27∫C) the TM output is 3.0 V referenced to -In and varies

10 mV/∫C. TM accuracy is +/-5∫C. This feature is useful for

validating the thermal design of the system as well as

monitoring the VTM temperature in the final application.

+OUT/-OUT DC Voltage Output Ports

The output (+OUT) and output return (-OUT) are through two

sets of contact locations. The respective +OUT and ≠OUT

groups must be connected in parallel with as low an

interconnect resistance as possible. Within the specified input

voltage range, the Level 1 DC behavioral model shown in

Figure 19 defines the output voltage of the VTM. The current

source capability of the VTM is shown in the specification table.

To take full advantage of the VTM, the user should note the

low output impedance of the device. The low output impedance

provides fast transient response without the need for bulk POL

capacitance. Limited-life electrolytic capacitors required with

conventional converters can be reduced or even eliminated,

saving cost and valuable board real estate.

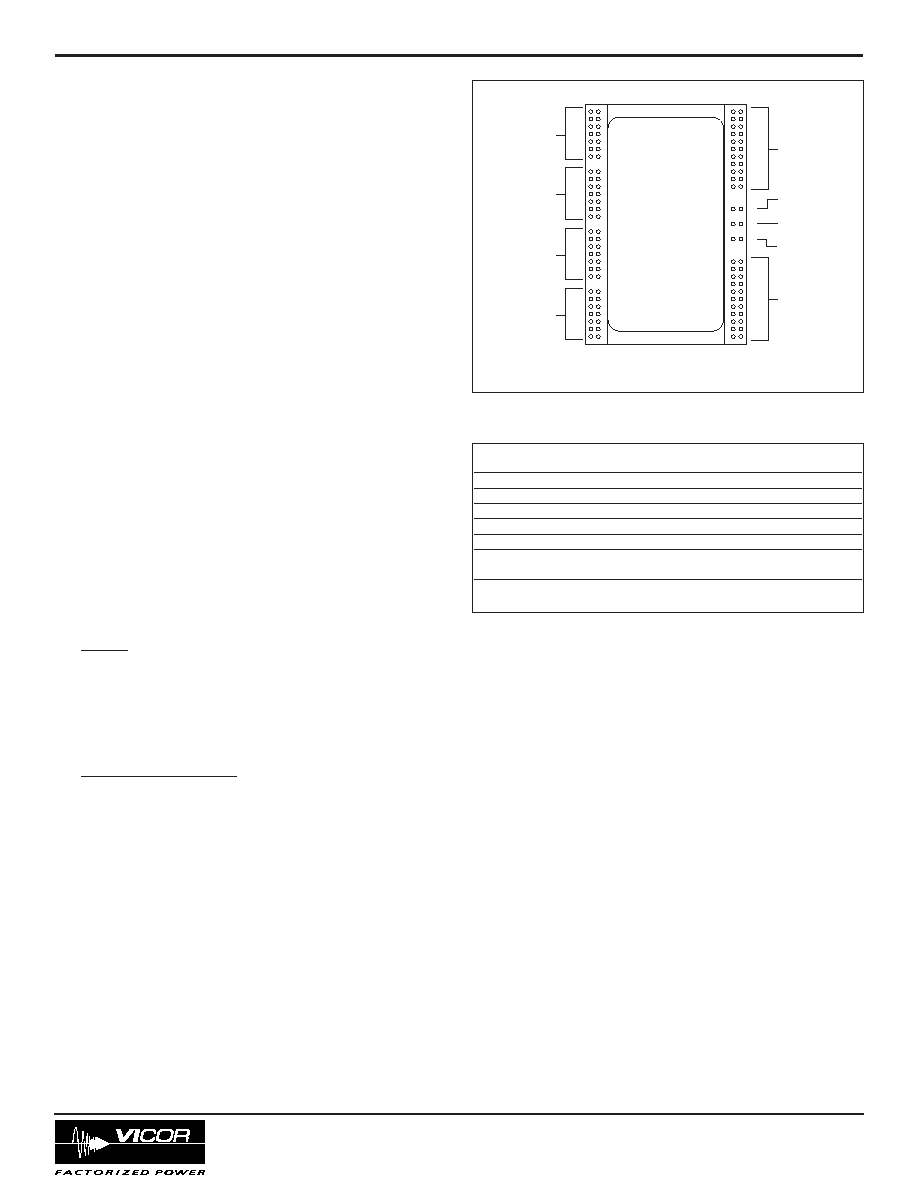

-In

Primary

Control

VTM Control

Temp.

Monitor

+In

-Out

+Out

-Out

+Out

Bottom View

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

T

U

V

W

Y

AA

AB

AC

AD

AE

AF

AG

AH

AJ

AK

AL

4 3 2 1

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

T

U

V

W

Y

AA

AB

AC

AD

AE

AF

AG

AH

AJ

AK

AL

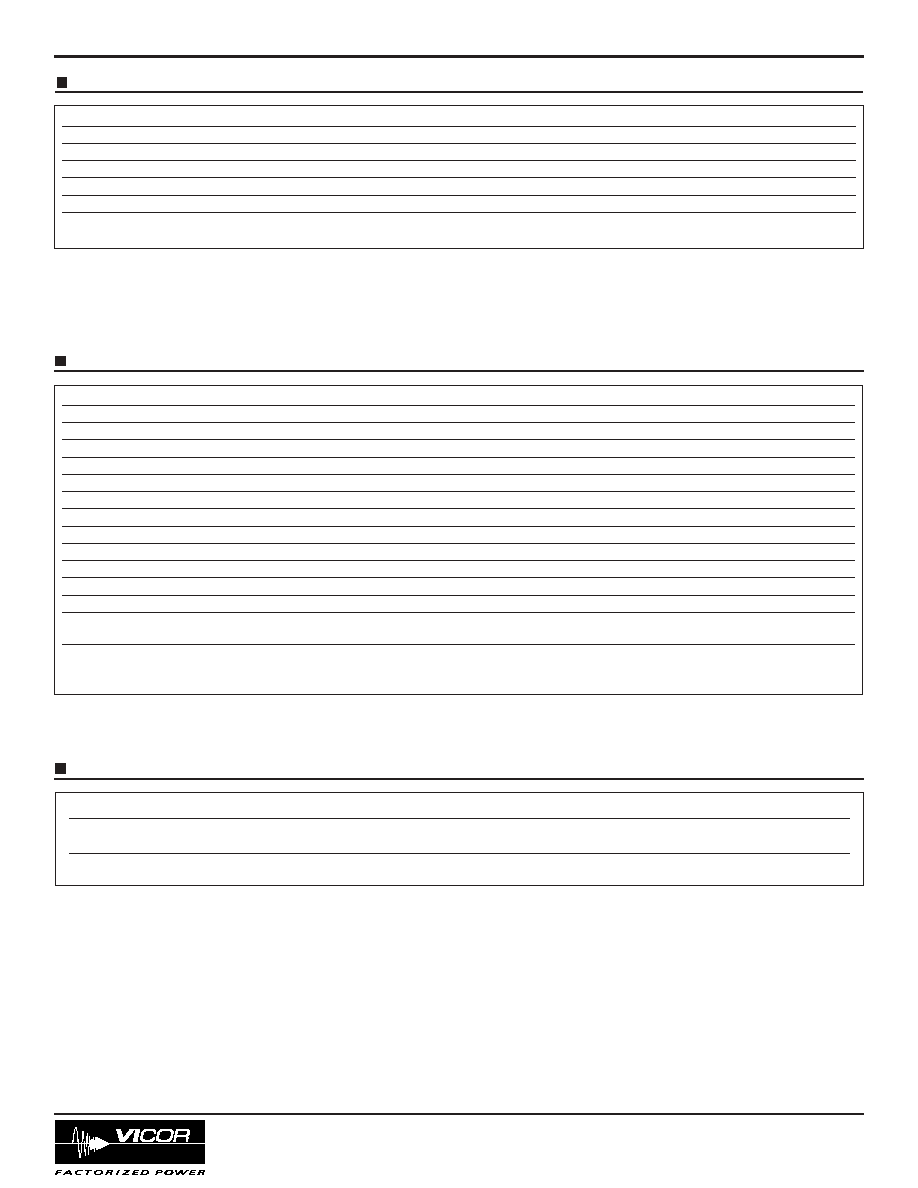

Figure 9--VTM BGA configuration

Signal BGA

Name

Designation

+In

A1-L1, A2-L2

≠In

AA1-AL1, AA2-AL2

TM

P1, P2

VC

T1, T2

PC

V1, V2

+Out

A3-G3, A4-G4,

U3-AC3, U4-AC4

≠Out

J3-R3, J4-R4,

AE3-AL3, AE4-AL4

Vicor Corporation

Tel: 800-735-6200 V∑I Chip Voltage Transformation Module V048K020T080 Rev. 1.2 Page 7 of 15

vicorpower.com

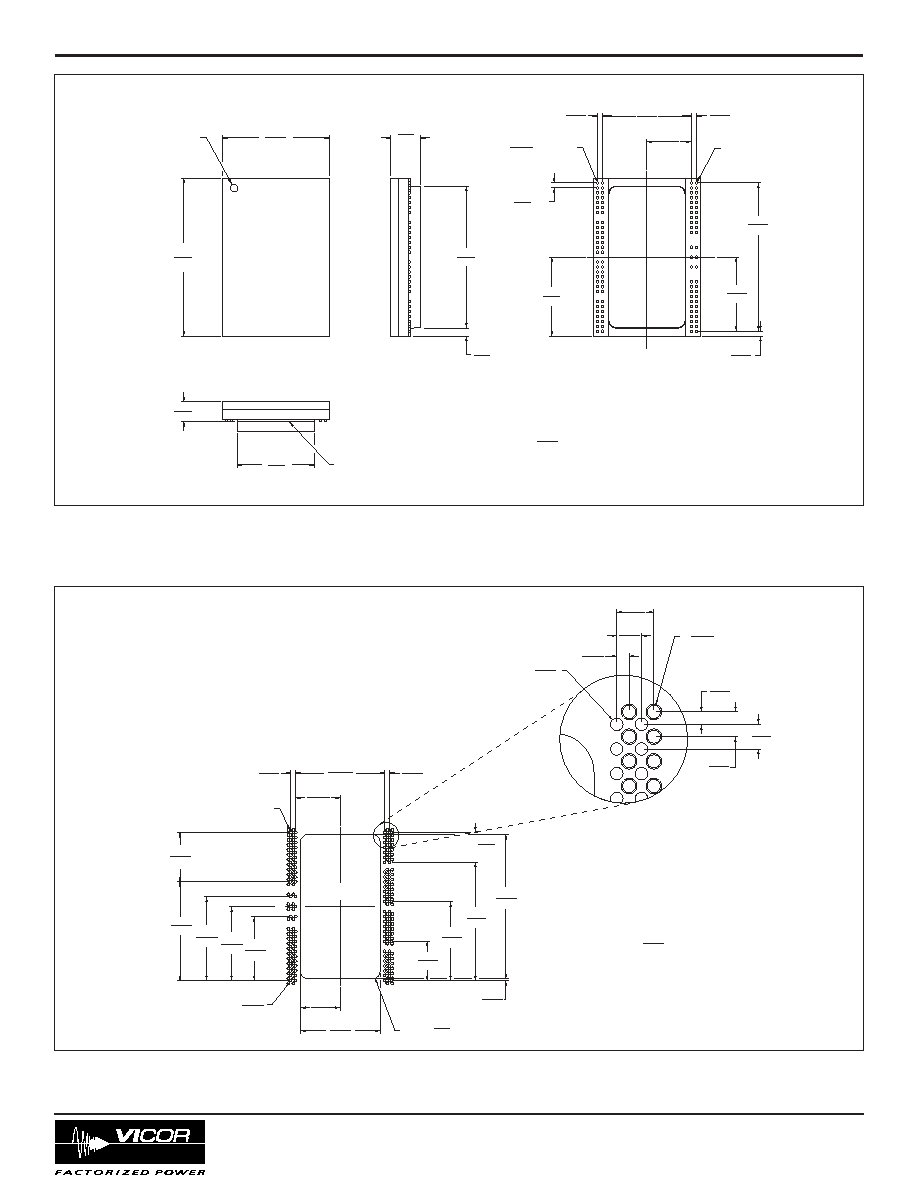

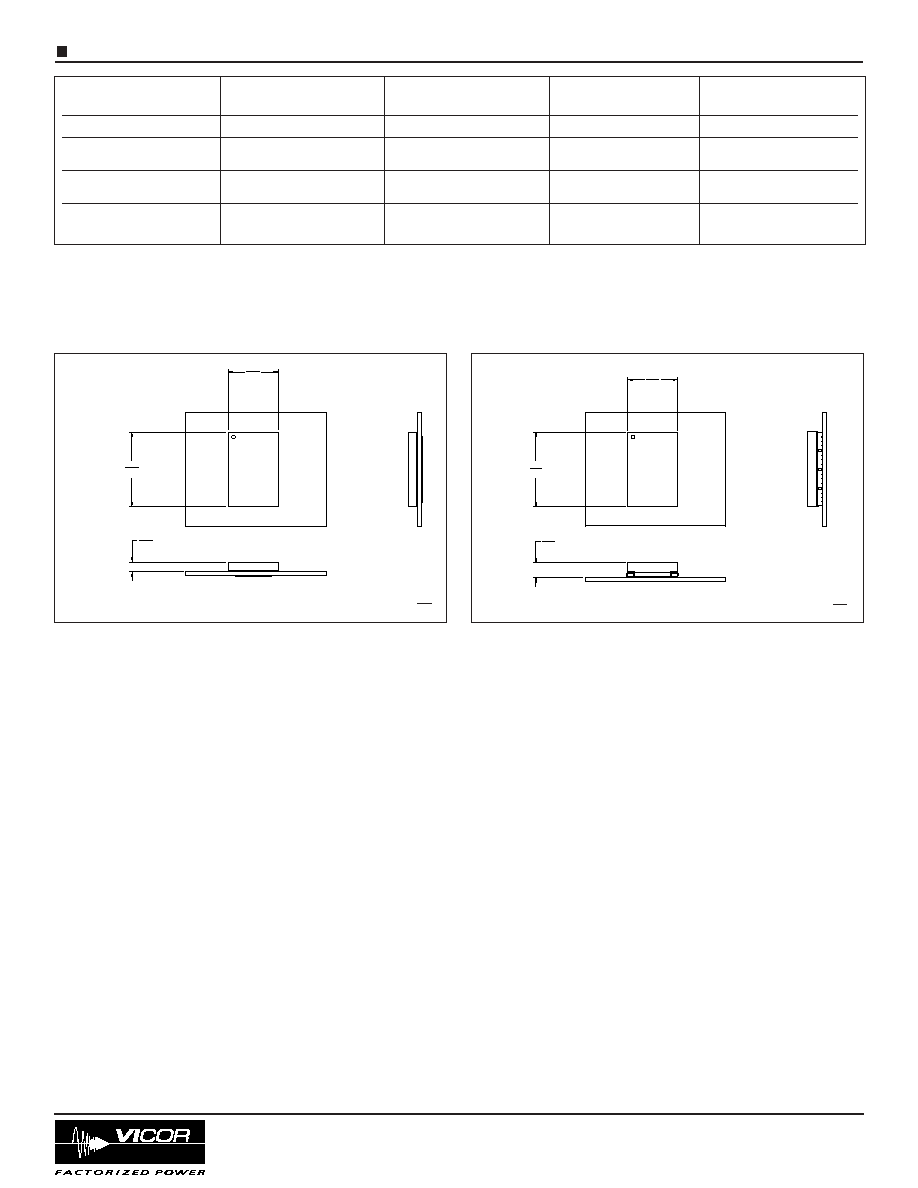

NOTES:

1- DIMENSIONS ARE .

2- UNLESS OTHERWISE SPECIFIED, TOLERANCES ARE:

.X/[.XX] = +/-0.25/[.01]; .XX/[.XXX] = +/-0.13/[.005]

3- PRODUCT MARKING ON TOP SURFACE

inch

mm

30,00

1.181

1,00

0.039

15,00

0.591

18,00

0.709

1,00

0.039

9,00

0.354

1,00

0.039

1,00

0.039

INPUT

OUTPUT

L

L

C

C

BOTTOM VIEW

SOLDER BALL #A1

SEATING PLANE

TOP VIEW (COMPONENT SIDE)

OUTPUT

INPUT

SOLDER BALL

#A1 INDICATOR

TYP

3,9

0.15

15,6

0.62

21,5

0.85

32,0

1.26

1,6

0.06

28,8

1.13

5,9

0.23

16,0

0.63

(106) X ÿ

0.51

0.020

SOLDER BALL

Mechanical Drawings

PRELIMINARY

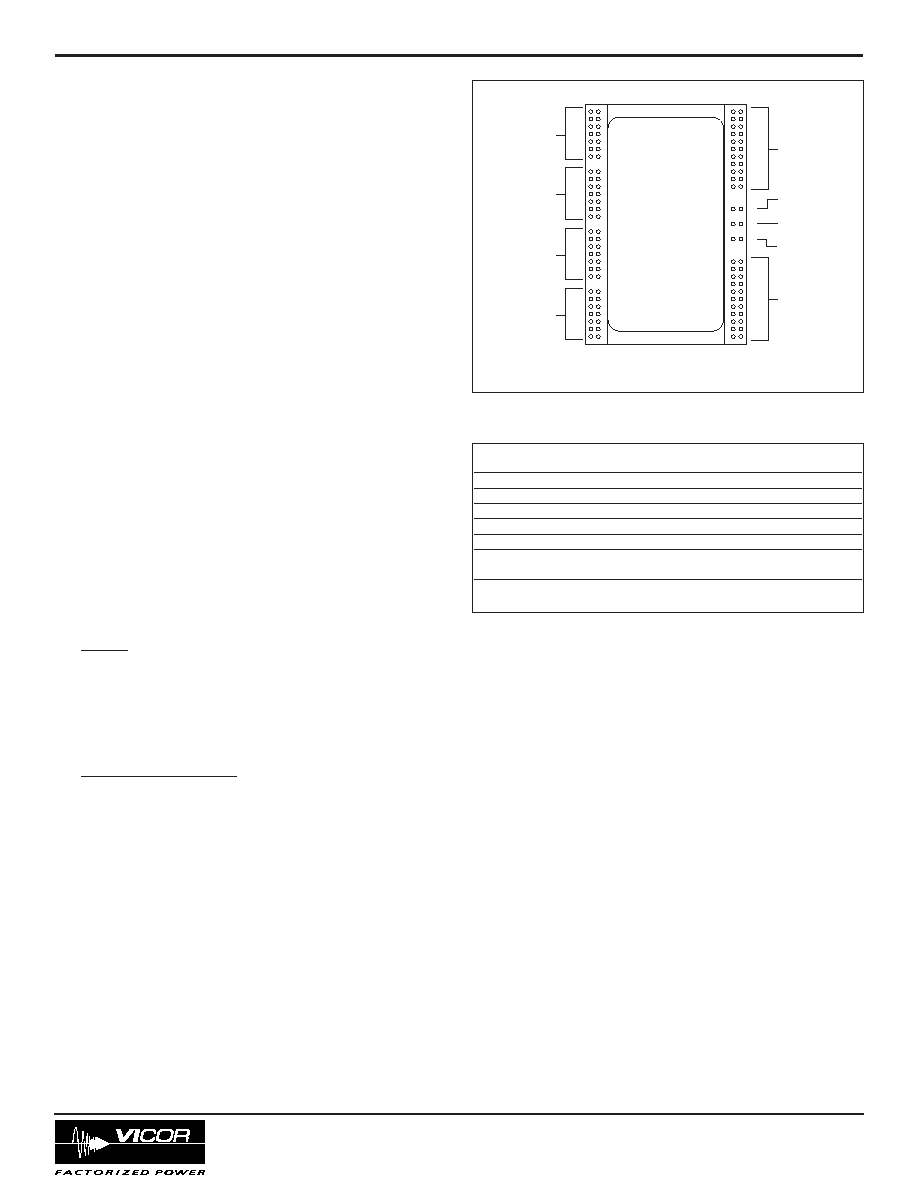

Figure 10-- V T M BGA mechanical outline; In-board mounting

NOTES:

1- DIMENSIONS ARE .

2- UNLESS OTHERWISE SPECIFIED, TOLERANCES ARE:

.X/[.XX] = +/-0.25/[.01]; .XX/[.XXX] = +/-0.13/[.005]

inch

mm

15,00

0.591

17,00

0.669

20,00

0.787

13,00

0.512

16,00

0.630

24,00

0.945

8,00

0.315

16,16

0.636

8,08

0.318

18,00

0.709

1,00

0.039

9,00

0.354

0,37

0.015

29,26

1.152

(2) X

0.394

(4) X

0.236

1,00

0.039

PCB CUTOUT

+IN

+OUT1

-OUT1

+OUT2

-OUT2

-IN

VC

TM

PC

SOLDER PAD #A1

RECOMMENDED LAND AND VIA PATTERN

(COMPONENT SIDE SHOWN)

SOLDER MASK

DEFINED PAD

1,6

0.06

0,51

0.020

1,00

0.039

1,50

0.059

0,50

0.020

1,00

0.039

0,50

0.020

1,00

0.039

SOLDER MASK

DEFINED PADS

CONNECT TO

INNER LAYERS

0,51

0.020

0,53

0.021

10,00

6,00

(106) X ¯

(4) X R

( ¯ )

( )

¯ PLATED VIA

( )

31

1

Figure 11-- VTM BGA PCB land/VIA layout information; In-board mounting

IN-BOARD MOUNTING

BGA surface mounting requires a

cutout in the PCB in which to recess the V∑I Chip

Vicor Corporation

Tel: 800-735-6200 V∑I Chip Voltage Transformation Module V048K020T080 Rev. 1.2 Page 8 of 15

vicorpower.com

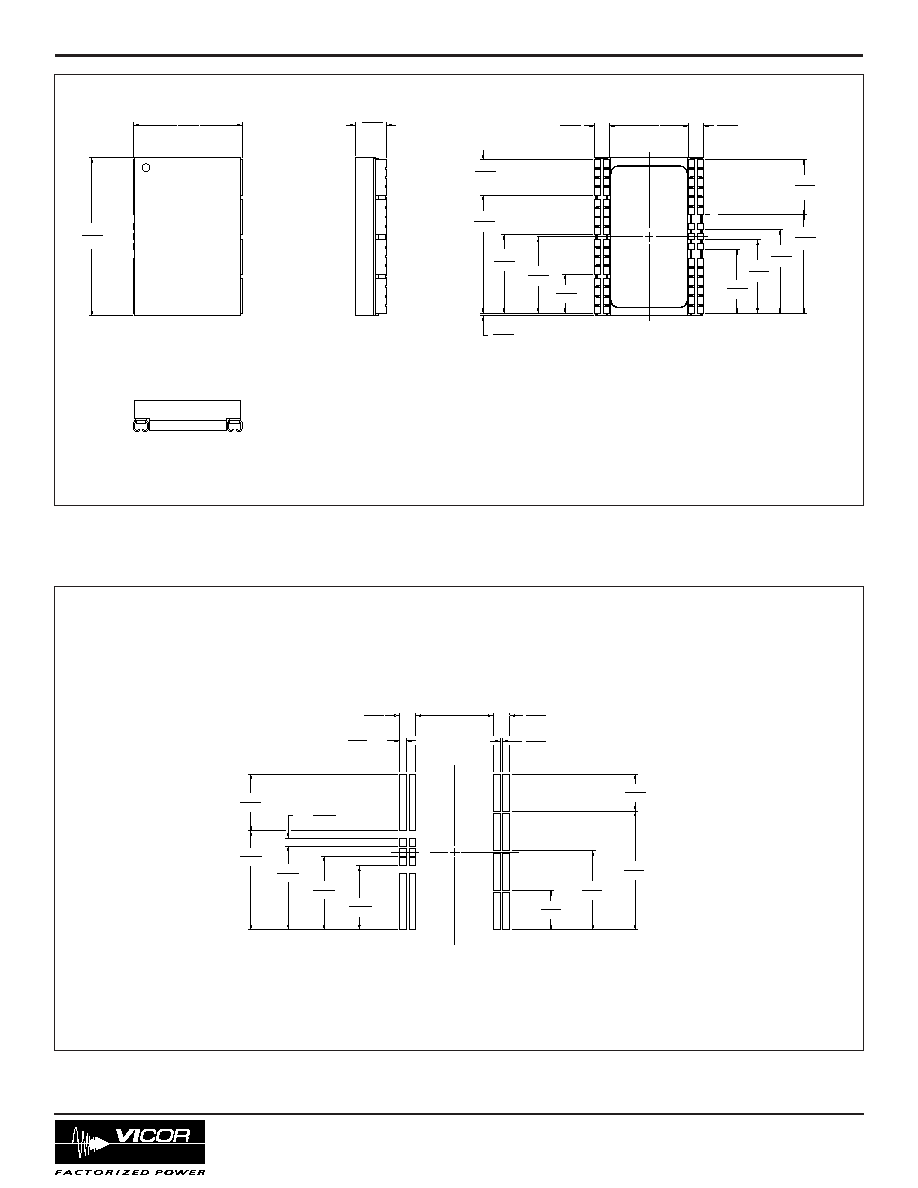

NOTES:

1- DIMENSIONS ARE mm/[INCH].

2- UNLESS OTHERWISE SPECIFIED, TOLERANCES ARE:

.X/[.XX] = +/-0.25/[.01]; .XX/[.XXX] = +/-0.13/[.005]

3- PRODUCT MARKING ON TOP SURFACE

C

CL

L

16,00

0.630

24,00

0.945

0,45

0.018

8,00

0.315

14,94

0.588

16,94

0.667

20,00

0.787

12,94

0.509

15,99

0.630

3,01

0.118

3,01

0.118

7,10

0.280

(4) PL.

11,10

0.437

(2) PL.

6,1

0.24

32,0

22,0

0.87

BOTTOM VIEW

OUTPUT

INPUT

OUTPUT

INPUT

TOP VIEW (COMPONENT SIDE)

1.26

15,55

0.612

Mechanical Drawings

PRELIMINARY

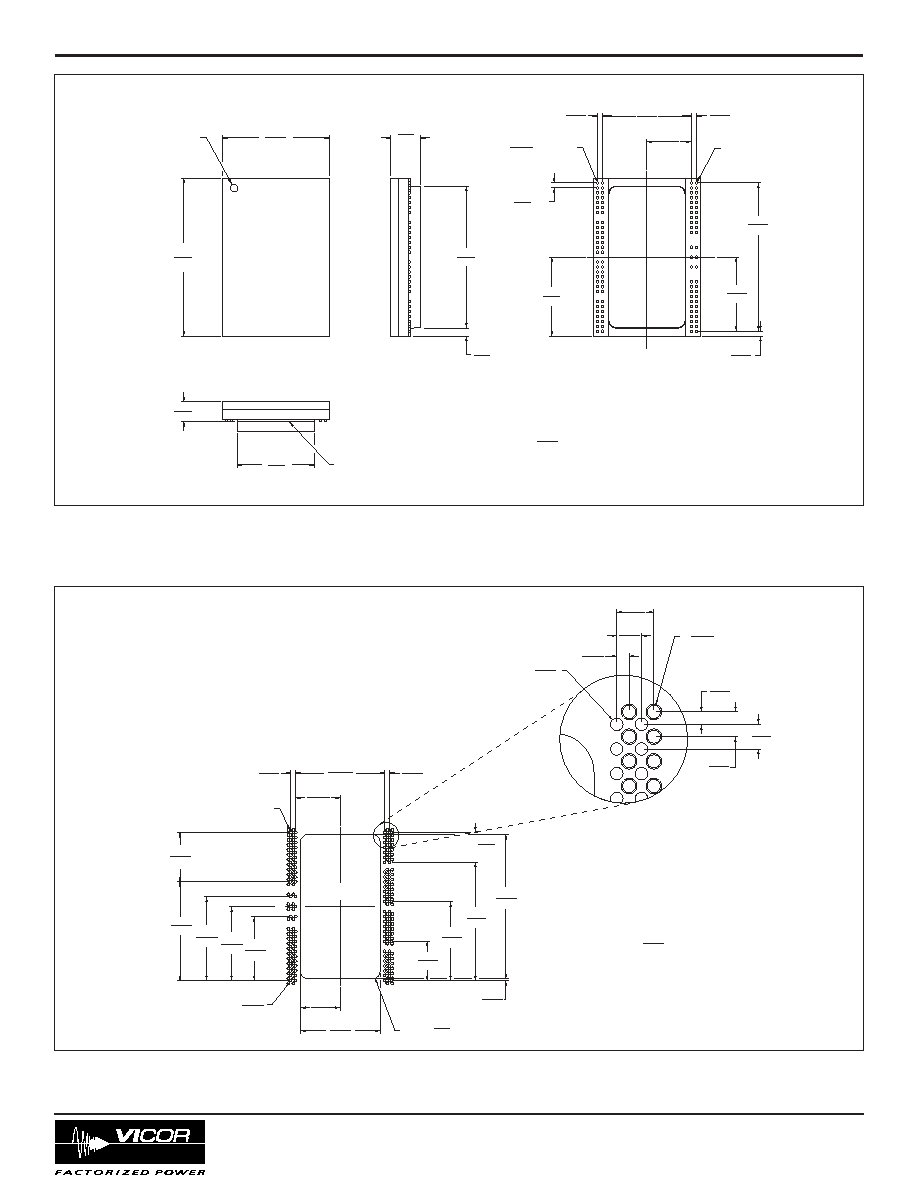

Figure 12-- V T M J-lead mechanical outline; On-board mounting

NOTES:

1- DIMENSIONS ARE mm/[INCH].

2- UNLESS OTHERWISE SPECIFIED, TOLERANCES ARE:

.X/[.XX] = +/-0.25/[.01]; .XX/[.XXX] = +/-0.13/[.005]

14,94

0.588

16,94

0.667

20,00

0.787

12,94

0.509

16,00

0.630

24,00

0.945

8,00

0.315

15,74

0.620

3,26

0.128

3,26

0.128

0,51

0.020

1,38

0.054

11,48

0.452

1,60

0.063

7,48

0.295

(COMPONENT SIDE SHOWN)

RECOMMENDED LAND PATTERN

-IN

PC

VC

TM

+IN

+OUT1

-OUT1

+OUT2

-OUT2

(4) X

(6) X

(2) X

(2) X

(2) X

(2) X

TYP

TYP

(8) X

(2) X

(2) X

(2) X

Figure 13-- VTM J-lead PCB land layout information; On-board mounting

Vicor Corporation

Tel: 800-735-6200 V∑I Chip Voltage Transformation Module V048K020T080 Rev. 1.2 Page 9 of 15

vicorpower.com

PRELIMIN

ARY

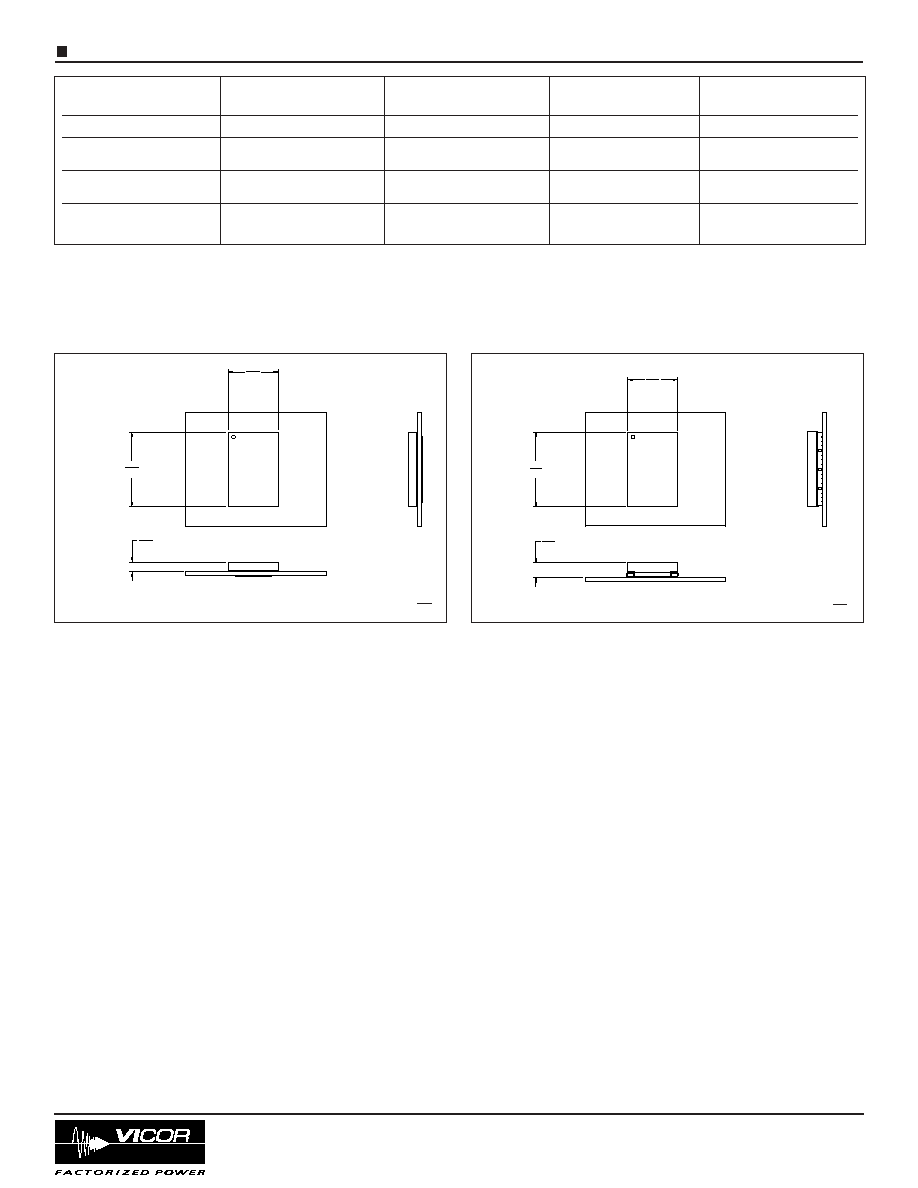

IN≠BOARD MOUNT

(V∑I Chip recessed into PCB)

21.5

0.85

32.0

1.26

4.0

0.16

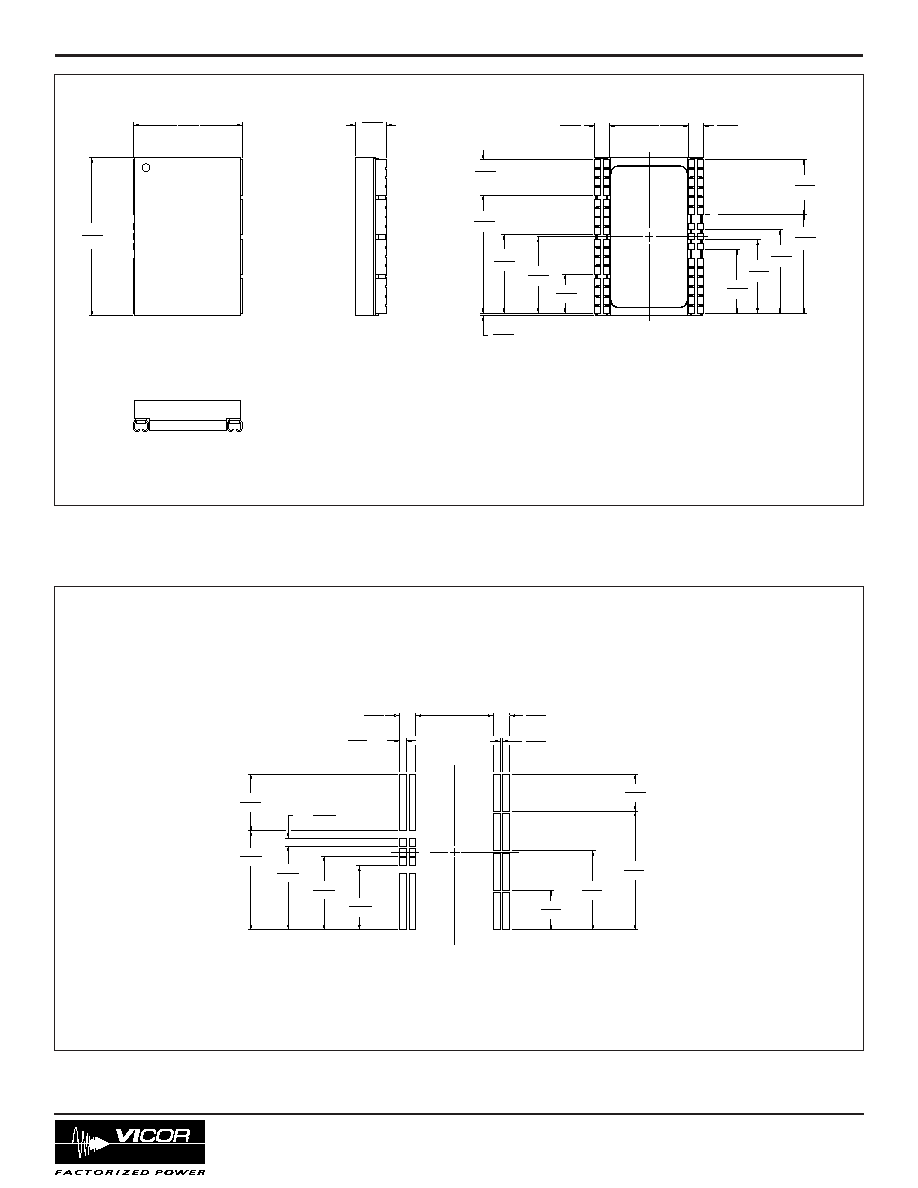

CONFIGURATION OPTIONS

CONFIGURATION

IN-BOARD* ON-BOARD* IN-BOARD WITH 0.25" ON-BOARD WITH 0.25"

(Fig. 14) (Fig. 15) HEATSINK HEATSINK

Effective Current Density

467 A/in

3

292 A/in

3

182 A/in

3

146 A/in

3

Junction-Board

2.1 ∞C/W

2.4 ∞C/W

2.1 ∞C/W

2.4 ∞C/W

Thermal Resistance

Junction-Case

1.1 ∞C/W

1.1 ∞C/W

N/A

N/A

Thermal Resistance

Junction-Ambient

6.5 ∞C/W

6.8 ∞C/W

5.0 ∞C/W

5.0 ∞C/W

Thermal Resistance 300LFM

*Surface mounted to a 2" x 2" FR4 board, 4 layers 2 oz Cu

Figure 14--In-board mounting ≠ package K

ON≠BOARD MOUNT

22.0

0.87

32.0

1.26

6.3

0.25

Figure 15--On-board mounting ≠ package F

mm

in

mm

in

Vicor Corporation

Tel: 800-735-6200 V∑I Chip Voltage Transformation Module V048K020T080 Rev. 1.2 Page 10 of 15

vicorpower.com

PRELIMINARY

Configuration Options (Cont.)

Figure 16--VTM test circuit

F1

Temperature Monitor

Load

+

≠

7 A

Fuse

C1

100

µ

F

Al electrolytic

+

≠

Input reflected ripple

measurement point

C2

0.47

µ

F

ceramic

+

≠

14 V

-In

PC

VC

TM

+In

-Out

+Out

VTM

+Out

-Out

K

Ro

Application Note

Parallel Operation

In applications requiring higher current or redundancy, VTMs

can be operated in parallel without adding control circuitry or

signal lines. To maximize current sharing accuracy, it is imperative

that the source and load impedance on each VTM in a parallel

array be equal. If VTMs are being fed by an upstream PRM, the

VC nodes of all VTMs must be connectd to the PRM VC.

To achieve matched impedances, dedicated power planes

within the PC board should be used for the output and output

return paths to the array of paralleled VTMs. This technique is

preferable to using traces of varying size and length.

The VTM power train and control architecture allow bi-directional

power transfer when the VTM is operating within its specified

ranges. Bi-directional power processing improves transient

response in the event of an output load dump. The VTM may

operate in reverse, returning output power back to the input

source. It does so efficiently.

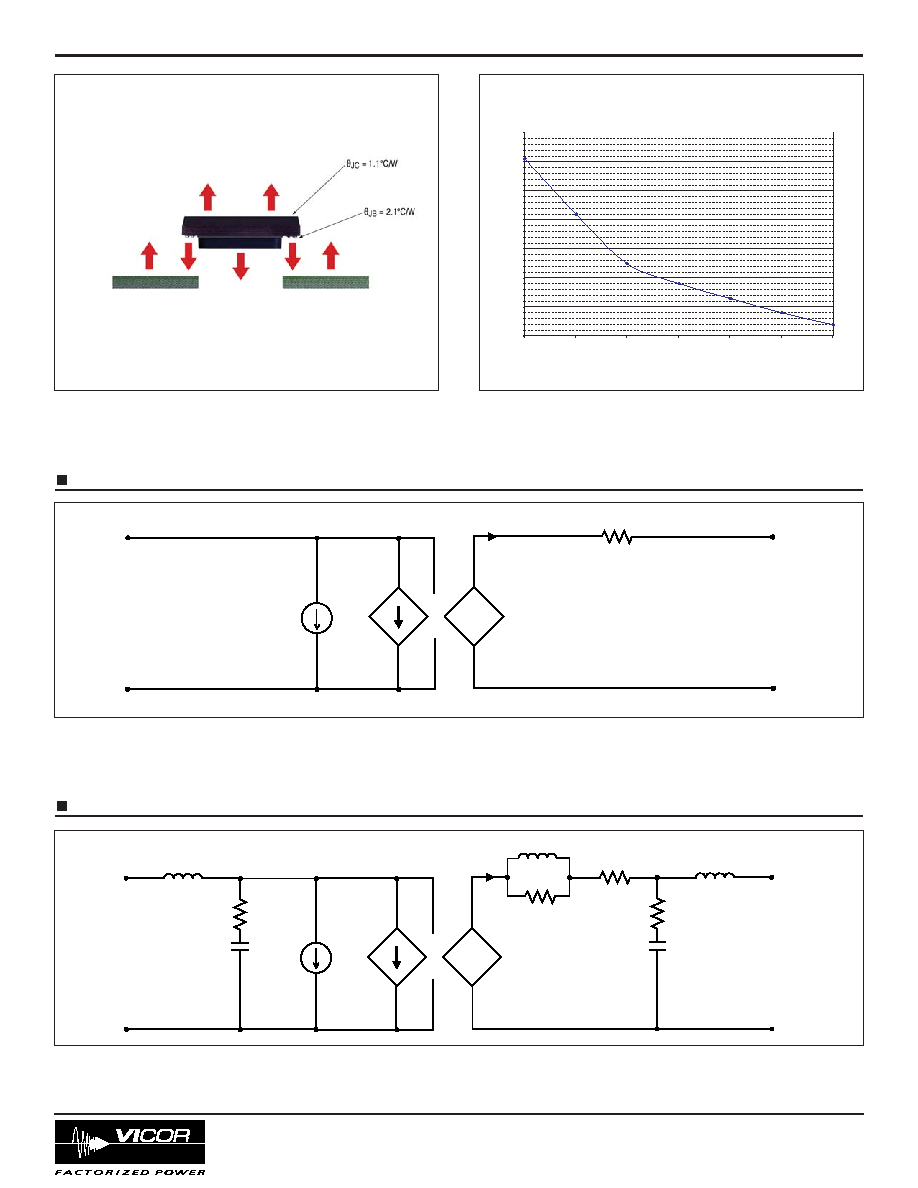

Thermal Management

The high efficiency of the VTM results in low power

dissipation minimizing temperature rise, even at full output

current. The heat generated within the internal semiconductor

junctions is coupled through very low thermal resistances, R

JC

and R

JB

(see Figure 17), to the PC board allowing flexible

thermal management.

CASE 1 Convection via optional heatsink to air

In an environment with forced convection over the surface

of a PCB with 0.4" of headroom, a VTM with a 0.25 heat sink

offers a simple thermal management option. The total

Junction toAmbient thermal resistance of a surface mounted

V048K020T080 with a heat sink attached is 4.8 ∫C/W in

300 LFMairflow, (see Figure 18).

At 2 Vout and full rated current (80A), the VTM dissipates

approximately 12 W per Figure 4. This results in a temperature

rise of approximately 56 ∫C, allowing operation in an air

temperature of 69 ∫C without exceeding the 125 ∫C max

junction temperature.

CASE 2 Conduction via the PC board to air

The low Junction to BGA thermal resistance allows the use

of the PC board as a means of removing heat from the VTM.

Convection from the PC board to ambient, or conduction to a

cold plate, enable flexible thermal management options.

With a VTM mounted on a 2.0 in

2

area of a multi-layer PC

board with appropriate power planes resulting in 8 oz of

effective copper weight, the Junction-to-BGA thermal

resistance, R

JA

, is 6.5 ∫C/W in 300 LFM of air. With a

maximum junction temperature of 125 ∫C and 12 W of

dissipation at full current of 80 A, the resulting temperature

rise of 76 ∫C allows the VTM to operate at full rated current

up to a 49 ∫C ambient temperature. See thermal resistances

on page 9 for additional details on this thermal management option.

Adding low-profile heat sinks to the PC board can lower the

thermal resistance of the PC board surrounding the VTM.

Additional cooling may be added by coupling a cold plate to

the PC board with low thermal resistance stand offs.

CASE 3 Combined direct convection to the air and conduction

to the PC board.

A combination of cooling techniques that utilize the power

planes and dissipation to the air will also reduce the total

thermal impedance. This is the most effective cooling

method. To estimate the total effect of the combination, treat

each cooling branch as one leg of a parallel resistor network.

Notes:

C3 should be placed close to the load

C3

100 µF

15 m

I

Q

52 mA

Vicor Corporation

Tel: 800-735-6200 V∑I Chip Voltage Transformation Module V048K020T080 Rev. 1.2 Page 11 of 15

vicorpower.com

Figure 18--Junction-to-ambient thermal resistance of VTM

with 0.25" Heat Sink.

VTM with 0.25'' heat sink

3

4

5

6

7

8

9

10

0

100

200

300

400

500

600

Airflow (LFM)

Tja

Application Note (continued)

PRELIMINARY

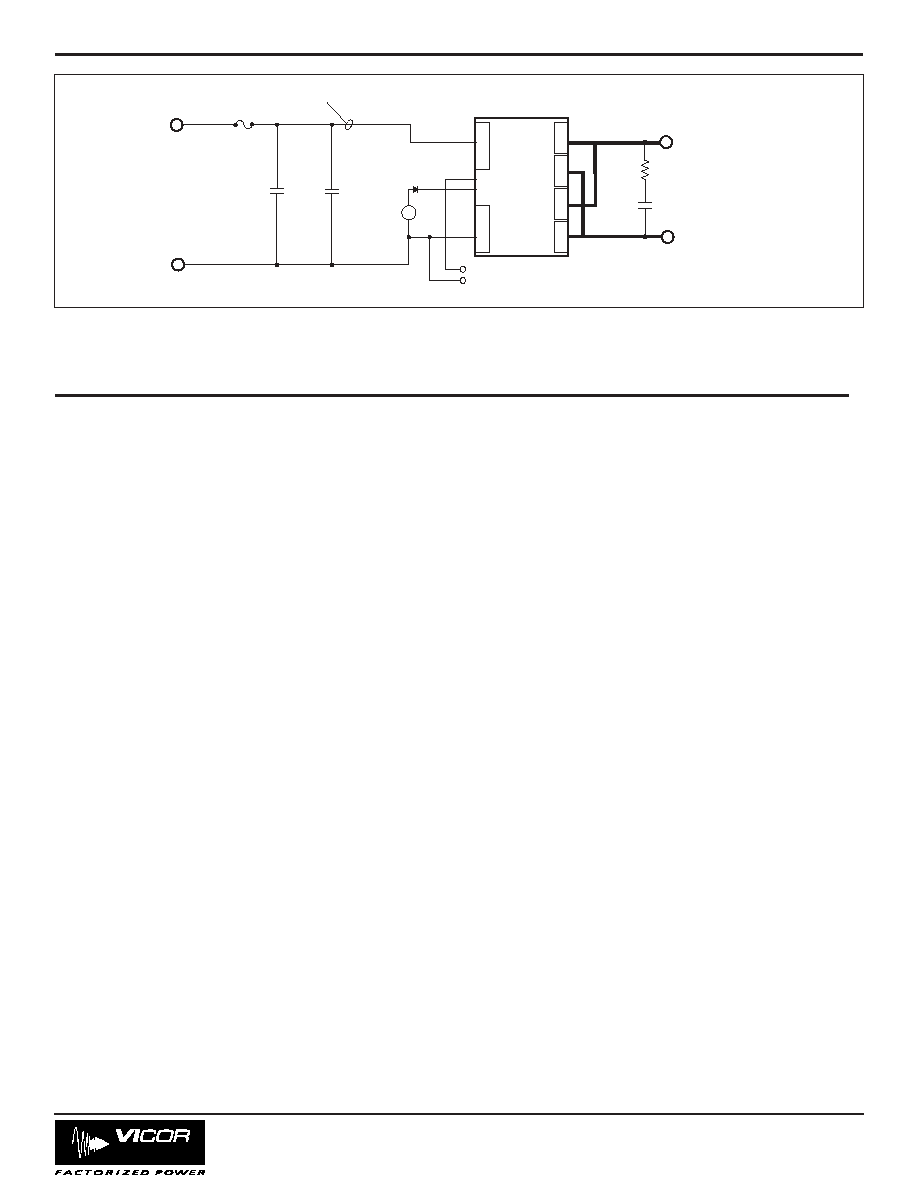

Figure 17--Thermal resistance

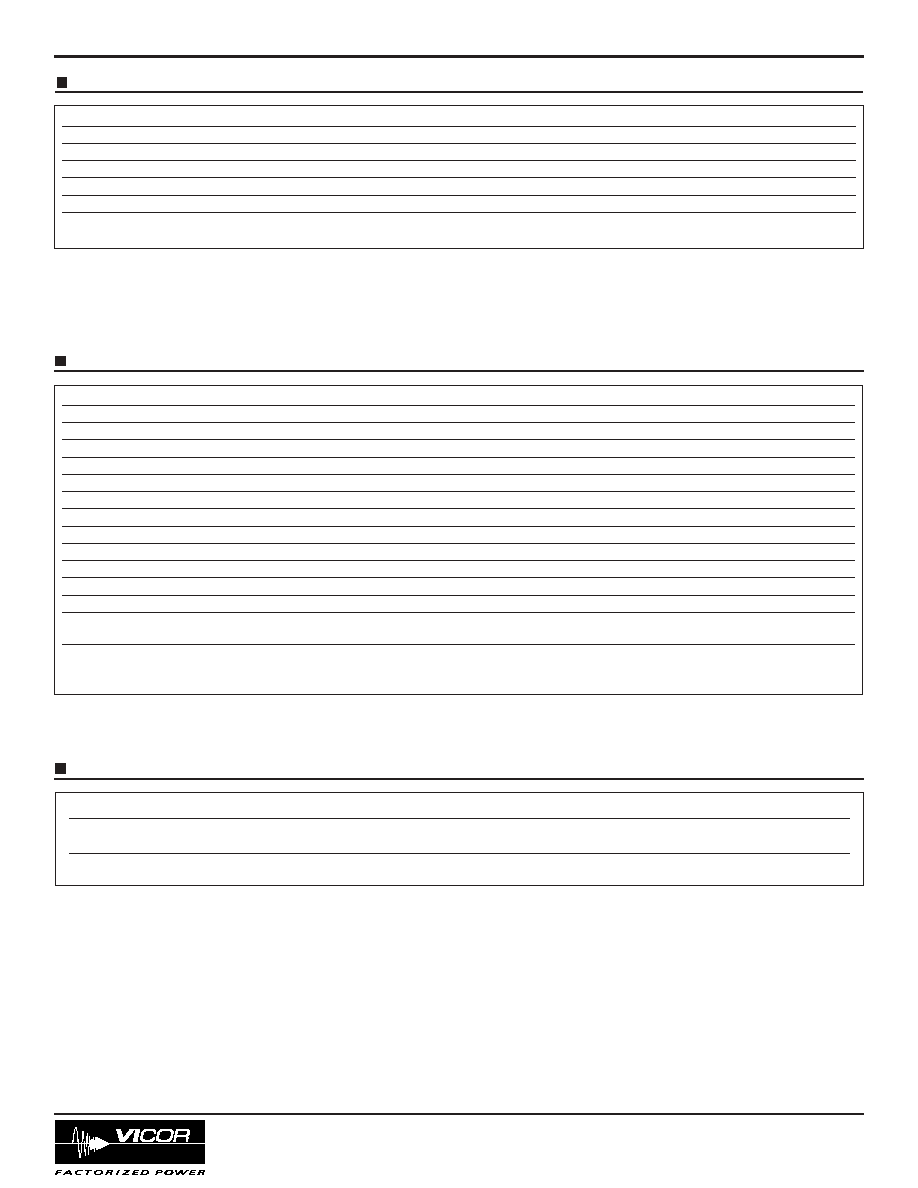

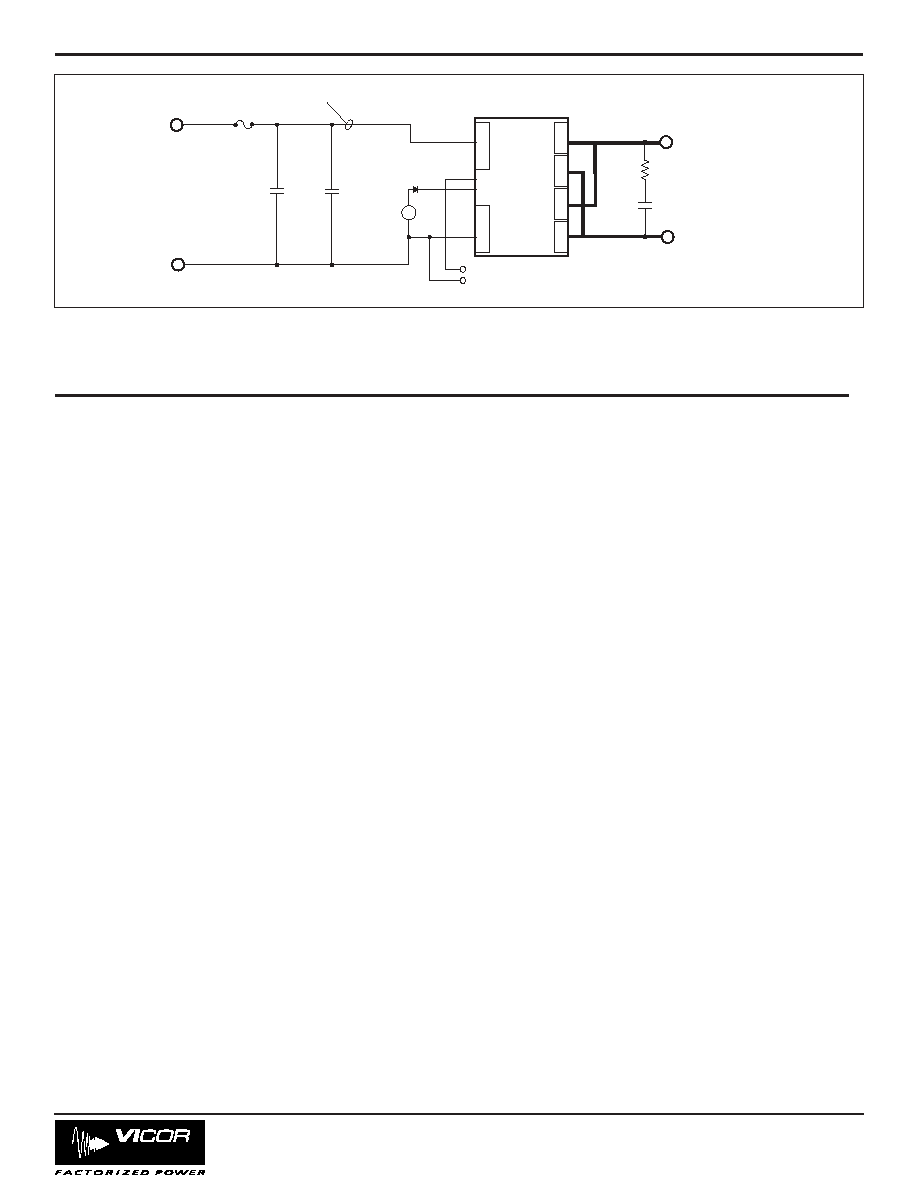

V∑I Chip VTM LEVEL 1 DC BEHAVIORAL MODEL for 48V to 2V, 80A

Figure 19--This model characterizes the DC operation of the V∑I Chip VTM, including the converter transfer function

and its losses. The model enables estimates or simulations of output voltage as a function of input voltage and output load, as

well as total converter power dissipation or heat generation.

©

+

≠

+

≠

V

OUT

C

OUT

V

IN

V

∑

I

K

+

≠

+

≠

C

IN

I

OUT

R

OUT

V∑I Chip VTM LEVEL 2 TRANSIENT BEHAVIORAL MODEL for 48V to 2V, 80A

Figure 20--This model characterizes the AC operation of the V∑I Chip VTM including response to output load or input voltage

transients or steady state modulations. The model enables estimates or simulations of input and output voltages under transient

conditions, including response to a stepped load with or without external filtering elements.

©

1.3 m

1/24 ∑ Vin

1/24 ∑ Iout

I

Q

52 mA

+

≠

+

-

V

OUT

V

IN

V

∑

I

K

+

≠

+

≠

I

OUT

R

OUT

1/24 ∑ Iout

1/24 ∑ Vin

1.3 m

L

I

N

= 20 nH

RC

I

N

1.3 m

0.12 nH

0.6 m

RC

OUT

65 µ

306 µF

L

OUT

= 0.8 nH

4 µF

Vicor Corporation

Tel: 800-735-6200 V∑I Chip Voltage Transformation Module V048K020T080 Rev. 1.2 Page 12 of 15

vicorpower.com

Application Note (continued)

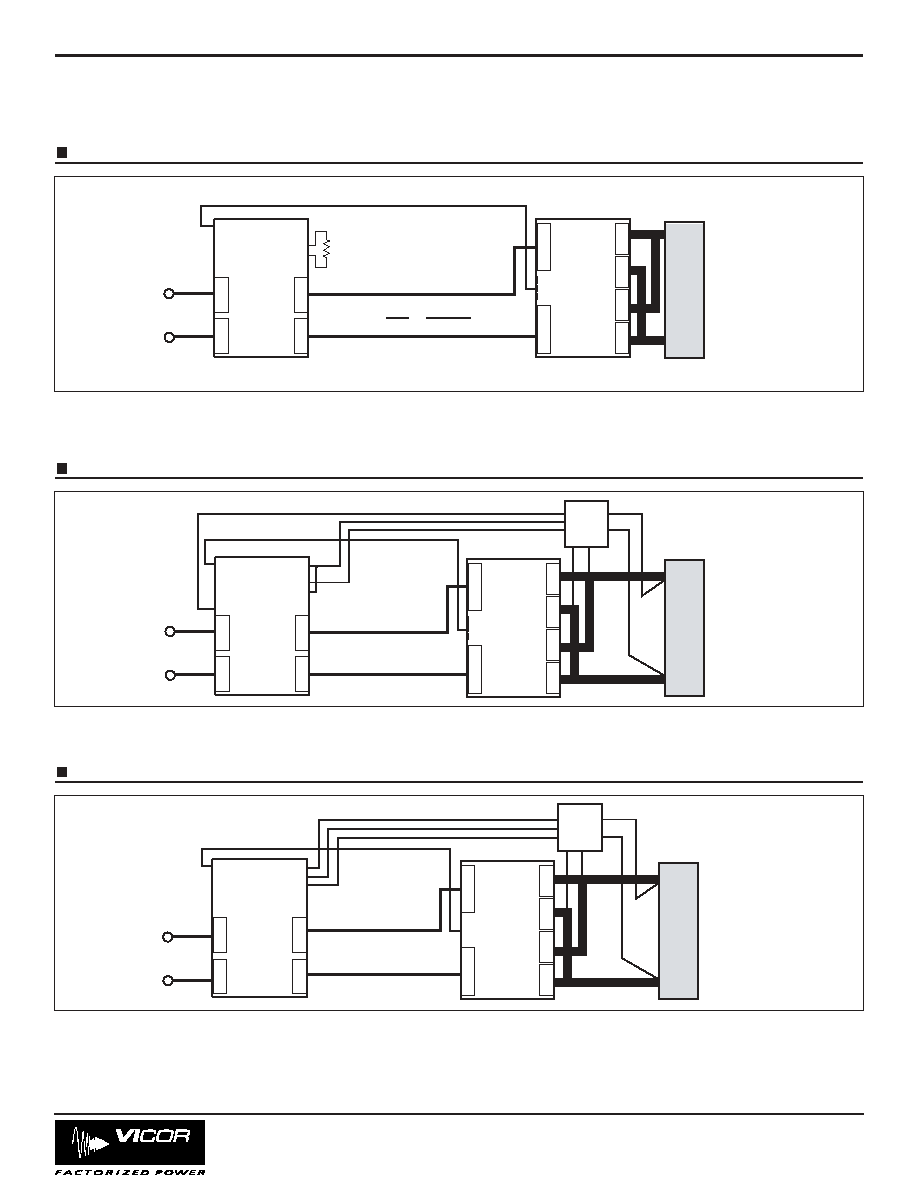

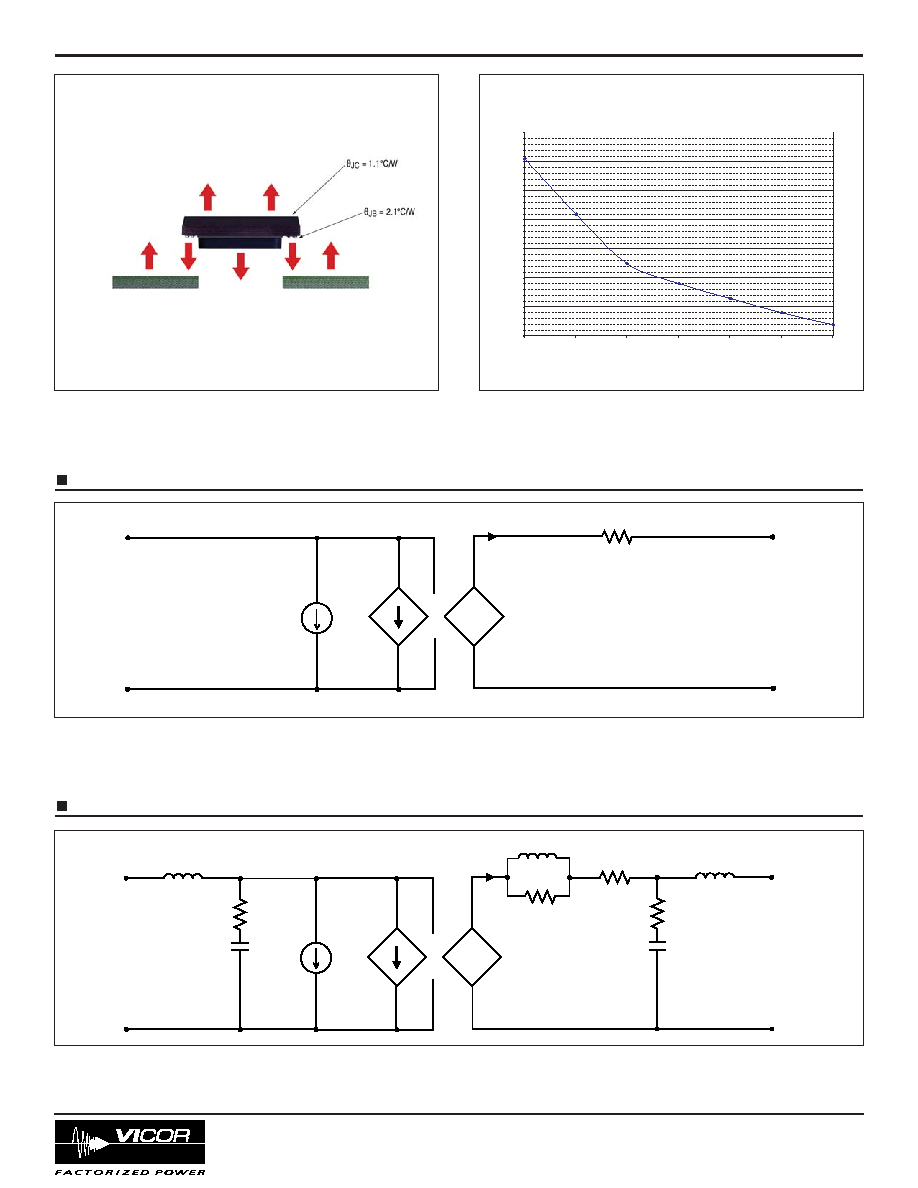

Figure 21 -- The PRM controls the factorized bus voltage, Vf, in proportion to output current to compensate for the output resistance,

Ro, of the VTM. The VTM output voltage is typically within 1% of the desired load voltage (V

L

) over all line and load conditions.

-In

PC

VC

TM

+In

-Out

+Out

VTM

+Out

-Out

K

Ro

+Out

≠Out

+In

≠In

VC

PC

TM

IL

VH

PR

NC

SG

SC

PRM-AL

OS

NC

CD

L

O

A

D

Factorized

Power Bus

Vin

Vo = V

L ±

1.0%

(Io∑Ro)

K

Rs

V

f

=

V

L

+

K

FPA Adaptive Loop

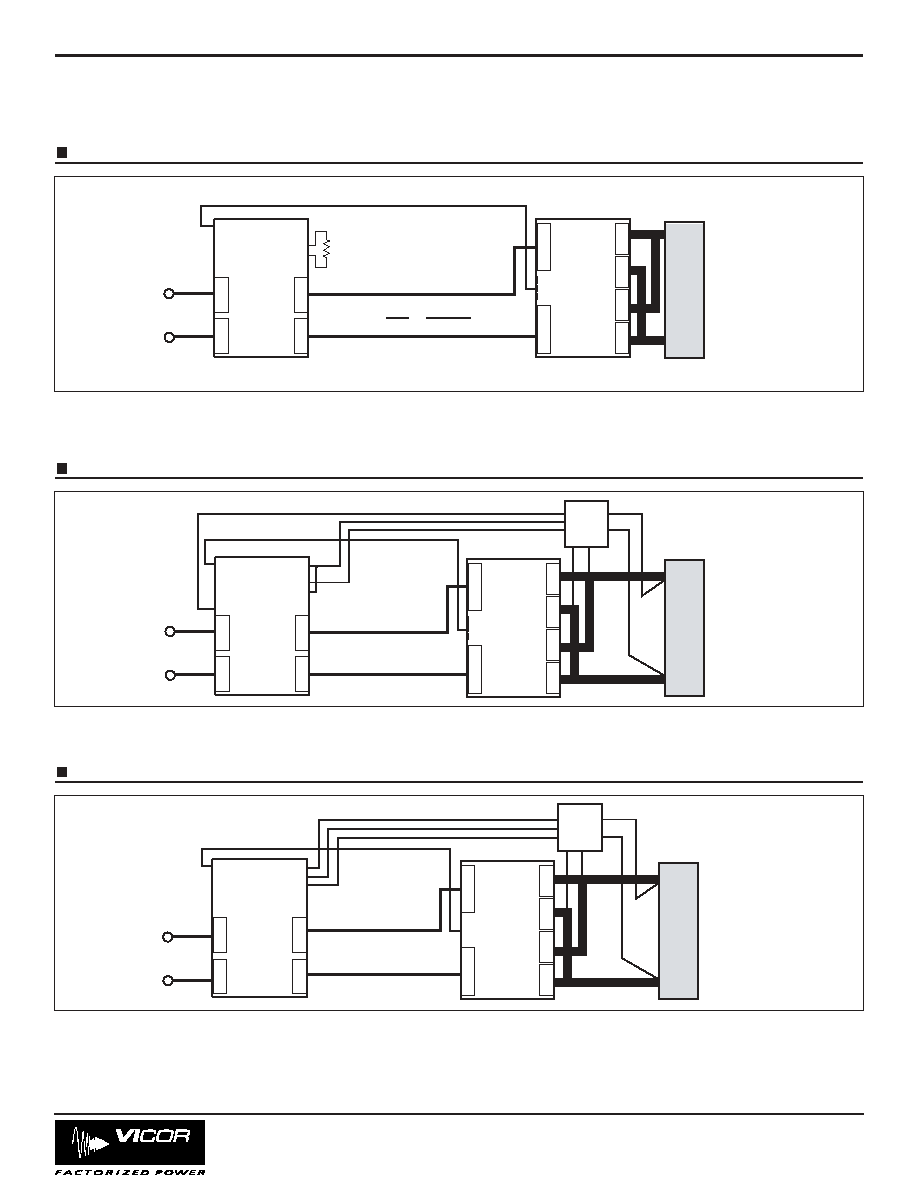

Figure 22 -- An external error amplifier or Point-of-Load IC (POLIC) senses the load voltage and controls the PRM output ≠ the

factorized bus ≠ as a function of output current, compensating for the output resistance of the VTM and for distribution resistance.

+Out

≠Out

+In

≠In

VC

PC

TM

IL

VH

PR

NC

SG

SC

PRM-AL

OS

NC

CD

-In

PC

VC

TM

+In

-Out

+Out

VTM

+Out

-Out

K

Ro

Remote

Loop

Control

V

f

= f (Vs)

L

O

A

D

Vin

Factorized

Power Bus

Vo = V

L ±

0.4%

+S

≠S

FPA Non-isolated Remote Loop

In figures 21 ≠ 24;

K = VTM Transformation Ratio

Vf = PRM Output (Factorized Bus Voltage)

Ro = VTM Output Resistance

Vo = VTM Output

V

L

= Desired Load Voltage

FPA Isolated Remote Loop

VC

PC

TM

IL

VS

PR

NC

FG

FB

PRM-IF

NC

NC

NC

+Out

≠Out

+In

≠In

-In

PC

VC

TM

+In

-Out

+Out

VTM

+Out

-Out

K

Ro

V

f

= f (Vs)

Factorized

Power Bus

Vin

Remote

Loop

Control

L

O

A

D

Vo = V

L ±

0.4%

+S

≠S

Figure 23--An external error amplifier or Point-of-Load IC (POLIC) senses the load voltage and controls the PRM output ≠ the

factorized bus ≠ as a function of output current, compensating for the output resistance of the VTM and for distribution

resistance. The factorized bus voltage (Vf) increases in proportion to load current. The remote feed back loop is isolated within

the PRM to support galvanic isolation and hipot compliance at the system level.

Vicor Corporation

Tel: 800-735-6200 V∑I Chip Voltage Transformation Module V048K020T080 Rev. 1.2 Page 13 of 15

vicorpower.com

Application Note (continued)

PRELIMINARY

V∑I Chip Soldering Recommendations

V∑I Chip modules are intended for reflow soldering processes.

The following information defines the processing conditions

required for successful attachment of a V∑I Chip to a PCB.

Failure to follow the recommendations provided can result in

aesthetic or functional failure of the module.

Storage

V∑I Chip modules are currently rated at MSL 5. Exposure to

ambient conditions for more than 72 hours requires a 24 hour

bake at 125∫C to remove moisture from the package.

Solder Paste Stencil Design

Solder paste is recommended for a number of reasons, including

overcoming minor solder sphere co-planarity issues as well as

simpler integration into overall SMD process.

63/37 SnPb, either no-clean or water-washable, solder paste

should be used. Pb-free development is underway.

The recommended stencil thickness is 6 mils. The apertures

should be 20 mils in diameter for the In-Board (BGA)

application and 0.9-0.9:1 for the On-Board (J-Leaded).

Pick & Place

In-Board (BGA) modules should be placed as accurately as

possible to minimize any skewing of the solder joint; a maximum

offset of 10 mils is allowable. On-Board (J-Leaded) modules

should be placed within ±5 mils.

To maintain placement position, the modules should not be

subjected to acceleration greater than 500 in/sec

2

prior to reflow.

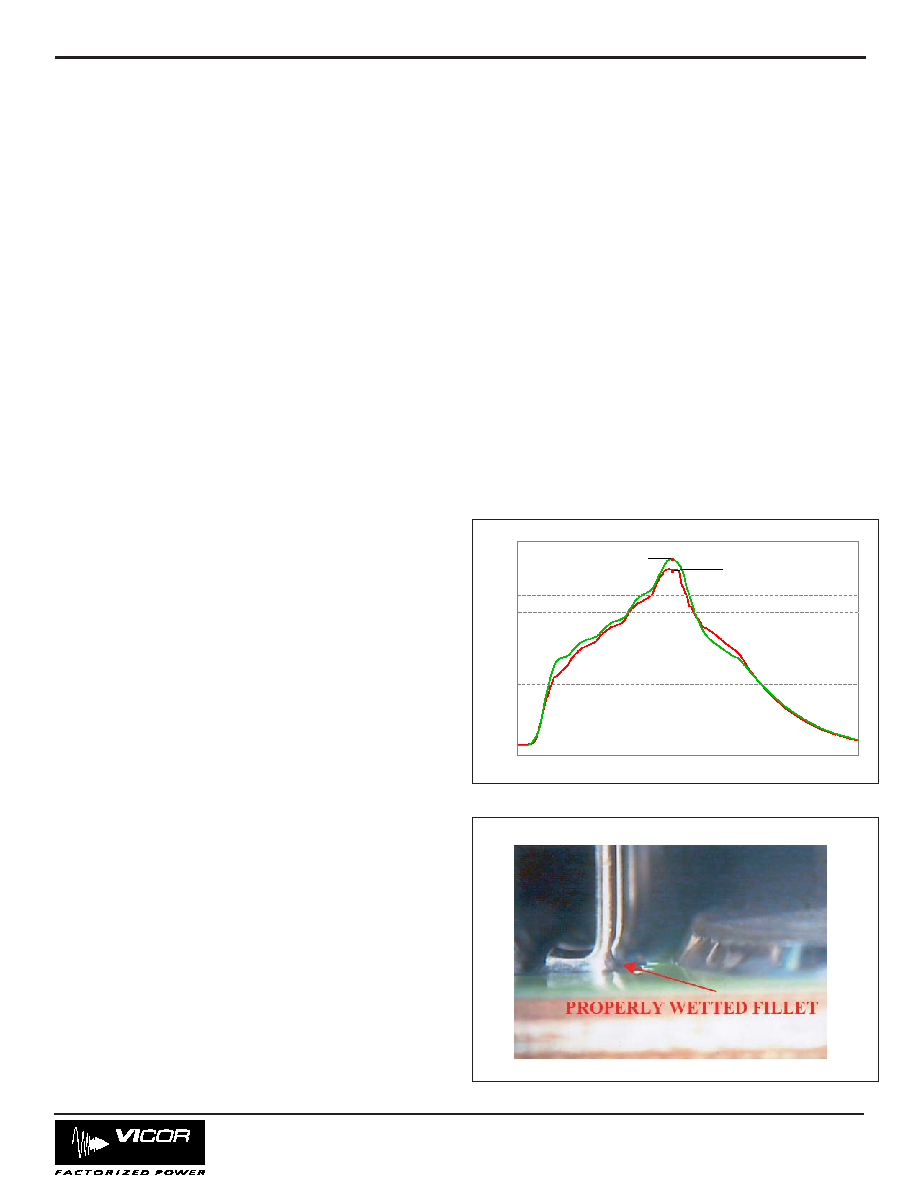

Reflow

There are two temperatures critical to the reflow process; the

solder joint temperature and the module's case temperature. The

solder joint's temperature should reach at least 220∫C, with a

time above liquidus (183∫C) of ~30 seconds.

The module's case temperature must not exceed 208 ∫C at

anytime during reflow.

Because of the

T needed between the pin and the case, a forced-

air convection oven is preferred for reflow soldering. This

reflow method generally transfers heat from the PCB to the

solder joint. The module's large mass also reduces its

temperature rise. Care should be taken to prevent smaller

devices from excessive temperatures. Reflow of modules onto a

PCB using Air-Vac-type equipment is not recommended due to

the high temperature the module will experience.

Inspection

For the BGA-version, a visual examination of the post-reflow

solder joints should show relatively columnar solder joints with

no bridges. An inspection using x-ray equipment can be done,

but the module's materials may make imaging difficult.

The J-Lead version's solder joints should conform to IPC 12.2

∑ Properly Wetted Fillet must be evident

∑ Heel fillet height must exceed lead thickness plus solder thickness.

Removal and Rework

V∑I Chip modules can be removed from PCBs using special tools

such as those made by Air-Vac. These tools heat a very localized

region of the board with a hot gas while applying a tensile force

to the component (using vacuum). Prior to component heating

and removal, the entire board should be heated to 80-100∫C to

decrease the component heating time as well as local PCB

warping. If there are adjacent moisture-sensitive components, a

125∫C bake should be used prior to component removal to

prevent popcorning. V∑I Chip modules should not be expected to

survive a removal operation.

Case Temperature, 208∫C

Joint Temperature, 220∫C

239

165

91

16

degC

183

Soldering Time

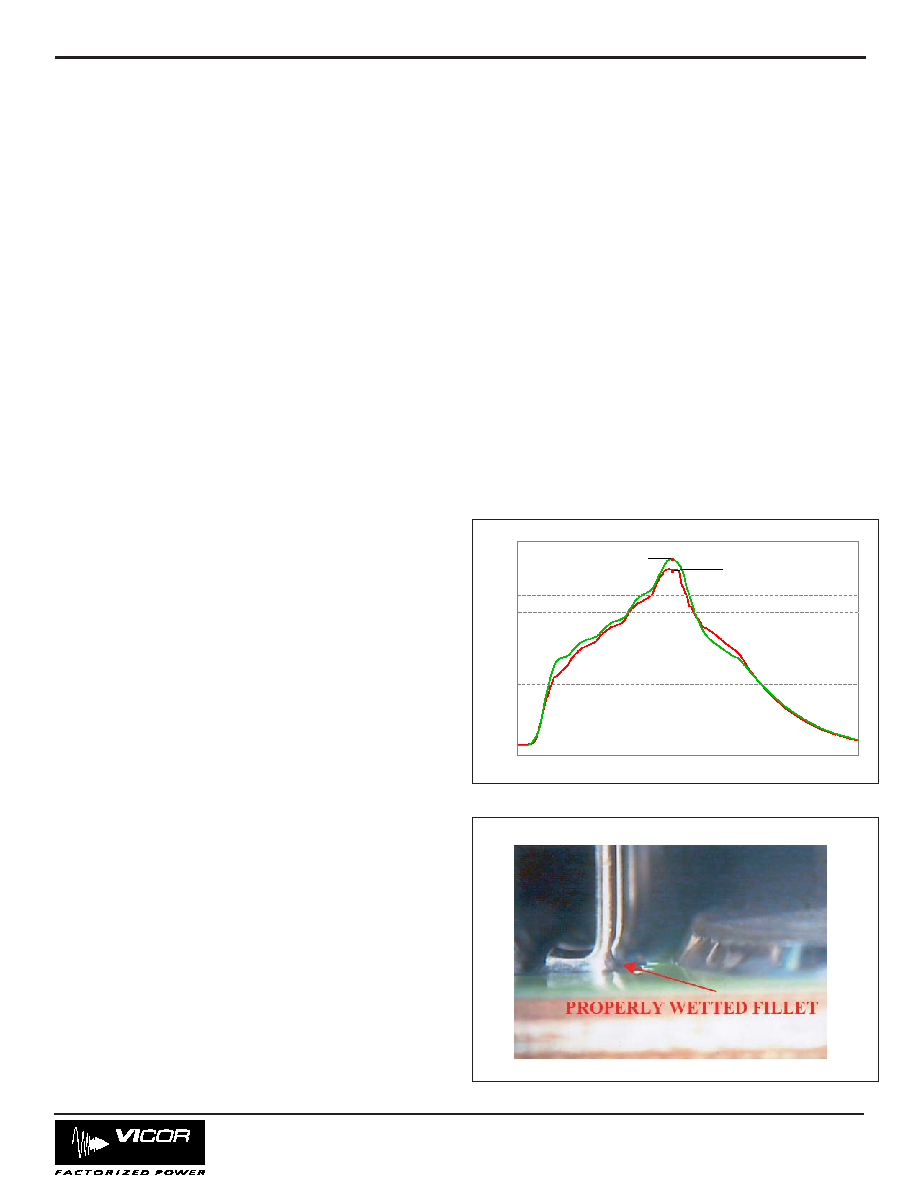

Figure 25--Thermal profile diagram

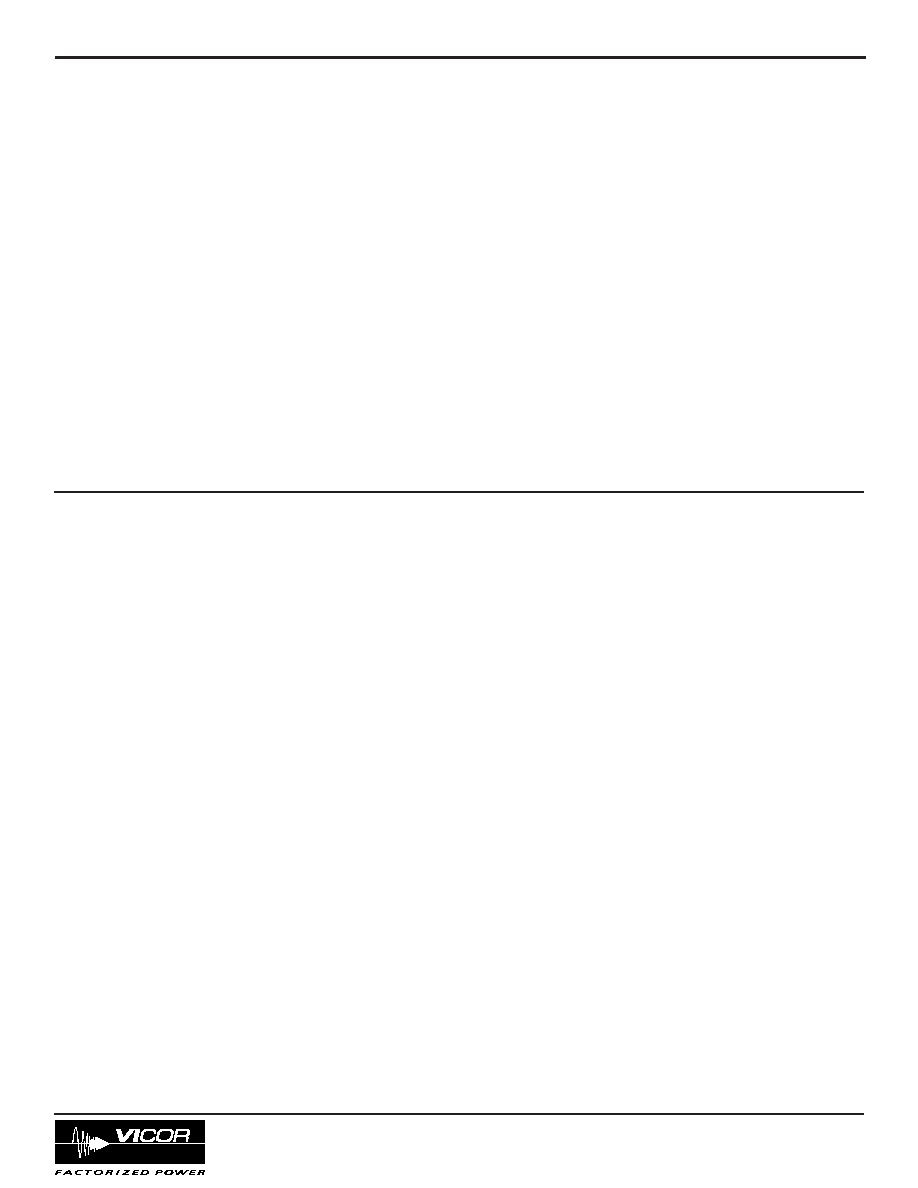

Figure 26-- Properly reflowed V∑I Chip J-Lead.

©

Vicor Corporation

Tel: 800-735-6200 V∑I Chip Voltage Transformation Module V048K020T080 Rev. 1.2 Page 14 of 15

vicorpower.com

Application Note (continued)

PRELIMINARY

Input Impedance Recommendations

To take full advantage of the VTM's capabilities, the impedance

of the source (input source plus the PC board impedance) must be

low over a range from DC to 5 MHz. The input of the VTM

(factorized bus) should be locally bypassed with a 8 µF low Q

aluminum electrolytic capacitor. Additional input capacitance

may be added to improve transient performance or compensate

for high source impedance. The VTM has extremely wide

bandwidth so the source response to transients is usually the

limiting factor in overall output response of the VTM.

Anomalies in the response of the source will appear at the output

of the VTM, multiplied by its K factor of 1/24. The DC

resistance of the source should be kept as low as possible to

minimize voltage deviations on the input to the VTM. If the

VTM is going to be operating close to the high limit of its input

range, make sure input voltage deviations will not trigger the

over voltage shutdown.

Input Fuse Recommendations

V∑I Chips are not internally fused in order to provide flexibility

in power system configuration. However, input line fusing of

V∑I Chips must always be incorporated within the power system.

A fast acting fuse, such as NANO2 FUSE 451 Series 7 A 125 V,

is required to meet safety agency Conditions of Acceptability.

The input line fuse should be placed in series with the +IN port.

Warranty

Vicor products are guaranteed for two years from date of shipment against defects in material or workmanship when in normal use

and service. This warranty does not extend to products subjected to misuse, accident, or improper application or maintenance. Vicor

shall not be liable for collateral or consequential damage. This warranty is extended to the original purchaser only.

EXCEPT FOR THE FOREGOING EXPRESS WARRANTY, VICOR MAKES NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED TO, THE WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Vicor will repair or replace defective products in accordance with its own best judgement. For service under this warranty, the buyer

must contact Vicor to obtain a Return Material Authorization (RMA) number and shipping instructions. Products returned without

prior authorization will be returned to the buyer. The buyer will pay all charges incurred in returning the product to the factory. Vicor

will pay all reshipment charges if the product was defective within the terms of this warranty.

Information published by Vicor has been carefully checked and is believed to be accurate; however, no responsibility is assumed for

inaccuracies. Vicor reserves the right to make changes to any products without further notice to improve reliability, function, or

design. Vicor does not assume any liability arising out of the application or use of any product or circuit; neither does it convey any

license under its patent rights nor the rights of others. Vicor general policy does not recommend the use of its components in life

support applications wherein a failure or malfunction may directly threaten life or injury. Per Vicor Terms and Conditions of Sale, the

user of Vicor components in life support applications assumes all risks of such use and indemnifies Vicor against all damages.

Vicor Corporation

Tel: 800-735-6200 V∑I Chip Voltage Transformation Module V048K020T080 Rev. 1.2 Page 15 of 15

vicorpower.com 06/05

Vicor's comprehensive line of power solutions includes high density AC-DC

and DC-DC modules and accessory components, fully configurable AC-DC

and DC-DC power supplies, and complete custom power systems.

Information furnished by Vicor is believed to be accurate and reliable. However, no responsibility is

assumed by Vicor for its use. Vicor components are not designed to be used in applications, such as life

support systems, wherein a failure or malfunction could result in injury or death. All sales are subject to

Vicor's Terms and Conditions of Sale, which are available upon request.

Specifications are subject to change without notice.

Vicor Corporation

25 Frontage Road

Andover, MA, USA 01810

Tel: 800-735-6200

Fax: 978-475-6715

Email

Vicor Express: vicorexp@vicr.com

Technical Support: apps@vicr.com

Intellectual Property Notice

Vicor and its subsidiaries own Intellectual Property (issued U.S. and Foreign Patents and

pending patent applications) relating to the product described in this data sheet including;

∑ The electrical and thermal utility of the V∑I Chip package

∑ The design of the V∑I Chip package

∑ The Power Conversion Topology utilized in the V∑I Chip package

∑ The Control Architecture utilized in the V∑I Chip package

∑ The Factorized Power Architecture.

Purchase of this product conveys a license to use it. However, no responsibility is assumed

by Vicor for any infringement of patents or other rights of third parties which may result

from its use. Except for its use, no license is granted by implication or otherwise under any

patent or patent rights of Vicor or any of its subsidiaries.

Anybody wishing to use Vicor proprietary technologies must first obtain a license. Potential

users without a license are encouraged to first contact Vicor's Intellectual Property Department.